SLIPSTRIP™ 2

Low capacity bearing slips made from dense extruded polyethylene sheet for fixed end rotation joints or as a low friction, structural slip membrane

Product Applications

SLIPSTRIP™ 2 is an economical low capacity, low friction bearing strip which can be used under in-situ or precast concrete slabs and beams, structural steelwork bearing plates and pipe supports to form a thin sliding joint. It is extruded from specially formulated polyethylene to form a durable laminate which is resistant to most chemicals, solvents and weathering.

Slipstrip 2 is therefore ideal as a permanent bearing strip in all conditions of exposure subject to the loading conditions. The bearing strips are formed by layering two sheets together, smooth to smooth face, with drafting tape or similar to prevent the ingress of fines and concrete grout between the sliding faces.

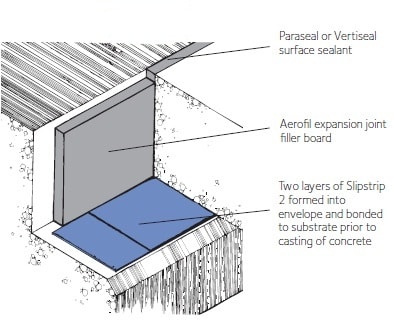

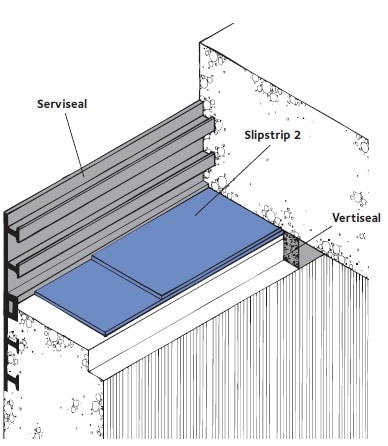

The textured bottom layer is then bonded on to a smooth true bearing substrate with Pak Adhesive. Concrete is then cast onto the top layer. Two layers of Slipstrip 2 can also be used for sliding wall joints, pre-stressed, posttensioned circular concrete tanks or similar structures provided the safe load bearing capacity is not exceeded.

| Performance | |

|---|---|

| Slipstrip 2 | |

| Maximum load | 0.7 N/mm2 |

| Coefficient of static friction | 0.15 |

| Operating Temperature | -29⁰C to 50⁰C |

Installation

Do not bond into position when temperature is below +5°C.

The bearing substrates should have a steel float finish and be true, smooth, dry, free from dust and debris before bonding the two layers of Slipstrip 2 on to the surface.

Slipstrip 2 of the appropriate width must be formed into an enclosed envelope to prevent the ingress of fines and concrete grout by sealing the edges and all staggered joints with masking tape or similar prior to installation and pouring of concrete. The smooth faces must be married together with the textured faces on the outside.

Joints between layers should be staggered wherever possible and circular fabrications should be formed in short chord lengths with staggered joints.

Pak Adhesive should be applied by brush in a full bodied coat on to the bearing surface and to the textured face of Slipstrip 2. When touch dry the Slipstrip 2 should be offered carefully into position and well rolled to achieve full contact bonding. For full instruction on the use of Pak Adhesive refer to the application guide on the can.

Typical Rotation/Sliding Joint

All test results shown in this data sheet are determined under laboratory conditions and with the product sample taken directly from stock in its original packing without any alteration or modification of its component parts.

Product Advantages

- Economic - easily installed on flat surfaces without affecting bearing height

- Thin section - allows use in restricted areas; does not effect concrete cover

- Low coefficient of friction - prevents drag and spalling at extreme edges

- Deformable - accepts minor irregularities in concrete surfaces, prevents locking-up of bearing

- Positive separation - creates slip-plane between dissimilar building materials

- Slipstrip 2 - for sliding joints having a max load - 0.7 N/mm2 with coefficient of friction - 0.15

Details shown are typical illustrations only and not working drawings. For assistance with working drawings and additional technical advice please contact GCP Technical Services.

| Supply | ||

|---|---|---|

| Slipstrip™ 2 | ||

| 150 mm wide | 1.5 mm thick x 25 m rolls | |

| 300 mm wide | 1.5 mm thick x 25 m rolls | |

| Ancillary Products | ||

| Pak Adhesive | 5 litre can Full coverage 5 sq m per litre | |

| Complementary Materials | ||

| Serviseal external waterstops | For construction/expansion joints | |

| Servitite | Internal waterstops for critical structures | |

| Bituthene 4000/4000S | Flexible cold-applied sheet membranes for waterproofing reservoir roofs | |

| Aerofil 1, Aerofil 2 | Filler Boards, for expansion/movement joints | |

Material by Others: Masking tape to form slip layer envelope. Equipment by Others: Stanley knife for trimming.

Specification Clause

Two layers of Slipstrip 2 to be formed into an envelope to the nominated width shown on the detailed drawings and fixed in position with Pak Adhesive at the rate of 5 m2/litre on to a smooth true bearing surface, strictly in accordance with the manufacturer’s instructions and supplied by GCP Applied Technologies.

Health and Safety

There is no legal requirement for a Safety Data Sheet (SDS) for Slipstsrip 2. For Pak Adhesive read the product label and SDS before use. Users must comply with all risk and safety phrases. SDS’s can be obtained from GCP Applied Technologies or from our web site at gcpat.com.

gcpat.uk | United Kingdom customer service: +44 (0) 1480 478421

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

SLIPSTRIP is a trademark, which may be registered in the United States and/or other countries, of GCP Applied Technologies, Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2018 GCP Applied Technologies, Inc. All rights reserved.

© Copyright 2026 Saint-Gobain Construction Chemicals UK Limited. All rights reserved. This document is only current as of the last updated date stated below and is valid only for use in the United Kingdom. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.uk. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-05-13

https://gcpat.uk/en-gb/solutions/products/slipstrip-2