BITUTHENE® 8000 / 8000S membranes (UK/IE Version)

Advanced, self-adhesive membrane with unique HDPE composite film that provides superior physical properties for water and vapour proof application in sub-structures.

Product Description

GCP Applied Technologies (“GCP”) BITUTHENE® 8000/8000S membranes combine the proven BITUTHENE® adhesive technology with a unique, grey coloured carrier film to provide superior performance and easier installation. BITUTHENE® 8000/8000S membranes are extremely tough. Accidental damage which would otherwise be missed, is made more visible by the black compound showing through the light grey film.

Advantages

- Water and vapour proof - provides protection for basements, BS 8102:2009.

- Gas resistance - BITUTHENE® 8000 and 8000S membranes are certified by BBA to score 2 points as a gas resistant barrier (see BS 8485-2015+A1-2019, Table 7).

- Chemically resistant - provides effective external protection against most aggressive soils, contaminated ground water and hydrocarbons in suspension.

- Superior performance - 70 m hydrostatic pressure resistance with ultra low moisture transmission rate.

- Wide application “window” reduces delays - application temperature range from -5ºC to +35ºC and damp surface tolerant

- Unique composite film - engineered for strength, flexibility and a smooth finish.

- Facilitates quality assured installation - printed overlap line ensures minimum laps; light grey colour highlights accidental damage for simple patch repairs.

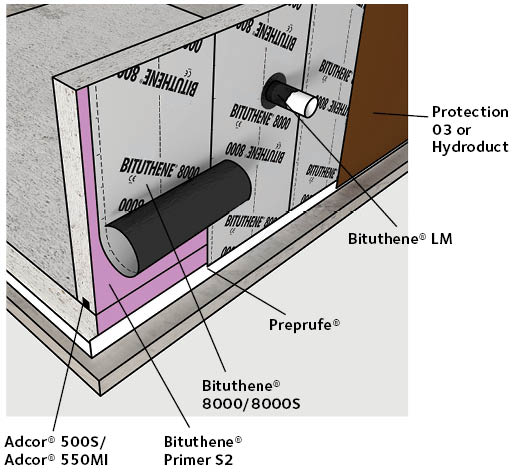

- System Compatibility -can be combined with PREPRUFE® pre-applied membranes, BITUTHENE® LM (E) Liquid Membrane, and HYDRODUCT® drainage composites and accessories for waterproofing system solutions.

This document is applicable to projects and applications in the UK only. Please refer to the local website for further information at gcpat.uk, or contact your GCP representative.

System Components

Membranes:

- BITUTHENE® 8000 Membrane for application to surfaces at ambient temperatures of -5°C to 20ºC

- BITUTHENE® 8000S Membrane for application to surfaces at ambient temperatures of 15°C to 35ºC

Ancillary Components (the most current Data Sheets for all system components are available on gcpat.uk or from your local GCP representative.)

- BITUTHENE® Primer S2 – required on all surfaces to which BITUTHENE® 8000/8000S Membranes are to be applied except below ground load bearing slabs and PREPRUFE® surfaces.

- BITUTHENE® Primer W2 - low VOC, water-based primer can be used as an alternative to BITUTHENE® Primer S2. as per specification and/or local site requirements.

- BITUTHENE® LM (E) – Two component, elastomeric, liquid applied detailing compound.

- Protection Board 03 – for application to in place BITUTHENE® Membranes before backfilling and to protect membrane from damage.

- ADCOR® 500S - Thick sectioned, conformable, hydro-expansive waterstop for preventing water entry through joints in concrete sub-structure.

- ADCOR® 550MI- Double protection system for construction joints using 2-in-1 pre-applied, post injectable hydrophilic waterstop.

- BITUSTIKTM 4000 and BITUSTIKTM BT- Double sided, self-adhesive, cold applied, waterproofing tape for membrane detailing and sealing.

- Pak Adhesive - a contact adhesive for bonding GCP boards to various substrates and membranes.

- HYDRODUCT® Drainage Sheet - High impact and creep resistant geo-composite and protection layer.

Limitations of Use

- Approved uses only include those uses specifically detailed in this product data sheet and other current product data sheets that can be found at gcpat.uk.

- BITUTHENE® Membranes are not intended for any other use. Contact GCP Technical Services where any other use is anticipated or intended.

- BITUTHENE® Membranes are designed where in-service temperatures will not exceed 130°F (54°C).

- BITUTHENE® 8000/8000S Membranes are not designed for permanent above ground exterior exposure

- Do not use BITUTHENE® Mastic to terminate BITUTHENE® Membranes to PREPRUFE® pre-applied waterproofing membrane systems. Terminations to PREPRUFE® membranes should only be done with BITUTHENE® LM (E).

- Do not apply BITUTHENE® Membranes over insulation or lightweight insulating concrete.

Note that because of local regulations, test standards and customs, product literature and offerings may be different in various locations. If you have any questions or comments, please contact your local customer service at info-gb@gcpat.com or +44 (0) 1480 478421.

Safety and Handling Information

Users must read and understand the product label and safety data sheet (SDS) for each system component. All users should acquaint themselves with this information prior to working with the products and follow the precautionary statements. SDSs can be obtained by contacting your local GCP representative or office, by calling GCP at +44 (0) 1480 478421.

Storage

- All products must be handled and stored consistent with BITUTHENE® 8000/8000S products methods statement.

- All BITUTHENE® Membranes should be stored upright.

- Observe one-year shelf life and use on a first in, first out basis.

- Store in dry conditions below 40ºC.

- Store off ground, under tarps or otherwise protected from rain and ground moisture.

Installation

Technical Support, Details and Technical Letters

The most up to date detail drawings and technical letters are available at gcpat.uk. For complete application instructions, please refer to the current GCP Applied Technologies Literature on (www.gcpat.uk). Documents in hardcopy as well as information found on websites other than www.gcpat.uk may be out of date or in error. Before using this product, it is important that information be confirmed by accessing the website and reviewing the most recent product information, including without limitation product data sheets and contractor manuals, technical bulletins, detail drawings and detailing recommendations. Please review all materials prior to installation of BITUTHENE® 8000 or BITUTHENE® 8000S Membrane. For technical assistance with detailing and problem solving please contact your local GCP representative or office, by calling GCP at +44 (0) 1480 478421.

Temperature

- Apply BITUTHENE® 8000 Membrane only in dry weather and when air and surface temperatures are between -5°C and 20ºC.

- Apply BITUTHENE® 8000S Membrane only in dry weather and when air and surface temperatures are between 15°C and 35°C.

- At air temperatures below +5°C measures should be taken to ensure that all surfaces are free from ice or frost.

- Apply BITUTHENE® Adhesive Primer S2 in dry weather above -5°C. (See separate product information sheet.)

Surface Preparation

Surfaces must be structurally sound and free of voids, spalled areas, loose aggregate and sharp protrusions. Remove contaminants such as grease, oil and wax from exposed surfaces. Remove dust, dirt, loose stone and debris. Concrete must be properly cured. Repair defects such as spalled or poorly consolidated areas. Remove sharp protrusions and form match lines. On masonry surfaces, apply a parge coat to rough concrete block and brick walls or trowel cut mortar joints flush to the face of the concrete blocks.

Priming

All surfaces (except under below ground load bearing slabs and PREPRUFE® Membranes) should be primed with one coat of GCP’s solvent based quick drying, damp and green concrete tolerant, BITUTHENE® Primer S2. Primer S2 can be applied by brush or roller. Primer S2 is pink in colour to ensure proper coverage, to aid identification and to avoid substitution of proper recommended primer.

BITUTHENE® 8000/ 8000S membrane Installation

Prior to beginning application of BITUTHENE® 8000/ 8000S membranes, all surfaces must be inspected to assure that they are free of frost, or condensation. Internal and external corners, penetrations and other “special” areas need to be fully detailed in accordance with GCP drawings and specifications with BITUTHENE® LM (E) in advance of placement of BITUTHENE® 8000/ 8000S membranes. After completion of the surface preparation and detailing, BITUTHENE® 8000/8000S membranes shall be laid by peeling back the protective release paper and applying the adhesive face onto the prepared surface.

Adjacent rolls are aligned using printed lines and overlapped 50 mm minimum at side and ends and well rolled with a firm pressure, using a lap roller to ensure complete adhesion and continuity between the layers. On high walls it may be necessary to batten fix the membrane to prevent slippage. Once the membrane is applied, cover with a protection board as soon as possible. On “green” concrete or damp surfaces, cover the membrane immediately.

Repairs, Protection & Drainage

- Damaged areas to be repaired with an oversize patch applied to a clean dry surface extending 100 mm beyond damage and firmly rolled.

- Protect BITUTHENE® membranes immediately after application to avoid damage from other trades, construction materials or backfill, using only Protection 03 boards.

- If the area around the substructure can be drained to a low level outlet then GCP recommends the use of HYDRODUCT® drainage sheets to help direct water away from the structure.

Performance

BITUTHENE® 8000/8000S membranes comply with the following national standards: BS 8102:2009, The Building Regulations (as amended) (England and Wales) 2000, The Building Regulations (Northern Ireland) 2000 (as amended), Building Standards (Scotland) Regulations 2004 (as amended).

Specification Clause

Refer to NBS Clause 180 and 190.

Supply

| BITUTHENE® 8000/8000S | 1 m x 20 m roll (20 sq m) Weight 36kg |

| BITUTHENE® Primer S2 | 5 & 25 litre can |

| Primer Coverage | 9-11 sq m per litre application, (depending on surface porosity and ambient temperature. |

Ancillary components:

Weights and measures as well as other important application and installation information can be found at gcpat.uk or by contacting your local GCP representative at info-gb@gcpat.com or +44 (0) 1480 478421.

Physical Properties

| Property | 8000 | 8000S |

| Colour | light grey | light grey |

| Application Temp | -5°C to 20°C | +15°C to +35°C |

| Resistance to hydrostatic head ASTM D5385 |

>70 m of water | >70 m of water |

| Declared values according to EN 13967 | |||

| Property | Declared Value | Test Method | |

| Visible defects - MDV | None | None | EN 1850-2 |

| Straightness - MDV | Pass | Pass | EN 1848-2 |

| Length (m) - MDV | 20.15 ± 0.15 | 20.15 ± 0.15 | EN 1848-2 |

| Thickness (mm) - MDV | 1.52 ± 0.08 | 1.52 ± 0.08 | EN 1849-2 |

| Width Carrier Sheet (m) - MDV | 0.987 ±0.007 | 0.987 ±0.007 | EN 1848-2 |

| Width Overall (roll) (m) - MDV | 1.000 ± 0.010 | 1.000 ± 0.010 | EN 1848-2 |

| Mass per unit area (g/m2) - MDV | 1490 ± 90 | 1550 ± 90 | EN 1849-2 |

| Water tightness to liquid water (at 60 kPa) | Pass | Pass | EN 1928 |

| Resistance to impact (Al-board (mm) - MLV) | ≥ 150 | ≥ 150 | EN 12691 |

| Resistance to tearing (Nail Shank)- unreinforced sheets (N) - MLV | ≥ 100 | ≥ 100 | EN 12310-1 |

| Joint strength (N/50mm) - MLV | ≥ 190 | ≥ 190 | EN 12317-2 |

| Water vapour transmission (μ= sD/d) - MDV |

105.000 ± 30% | 105.000 ± 30% | EN 1931 Method B |

| Durability of water tightness against ageing/degradation (at 60 kPa) | Pass | Pass | EN 1296 EN 1928 Method B |

| Durability of water tightness against chemicals (at 60 kPa) | Pass | Pass | EN 1847 Method B EN 1928 Method B |

| Durability of tensile properties against chemicals | Pass | Pass | EN 13967 Annex C |

| Compatibility with bitumen | Pass | Pass | EN 1548 |

| Resistance to static loading | ≥ 20 - Pass | ≥ 20 - Pass | EN 12730 |

| Tensile properties - unreinforced sheets (N/50mm) - MLV | Long1 ≥ 180 Trans2 ≥ 180 |

Long1 ≥ 180 Trans2 ≥ 180 |

EN 12311-2 Method A |

| Tensile properties - unreinforced sheets (Elongation at maximal tensile force %) - MLV | Long1 ≥ 5 Trans2 ≥ 5 |

Long1 ≥ 5 Trans2 ≥ 5 |

EN 12311-2 Method A |

| Reaction to fire (Class; test conditions) |

E | E | EN 13501-1 |

Footnotes:

1. Longitudinal - related to the roll direction

2. Transversal - related to the roll direction

3. MDV: Manufacturer Declared Value

4. MLV: Manufactured Limiting Value

5. NPD: No Performance Declared.

All declared values shown in this data sheet are based on test results determined under laboratory conditions and with the product sample taken directly from stock in its original packing without any alteration or modification of its component parts.

gcpat.uk | United Kingdom customer service: +44 (0) 1480 478421

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

ADCOR, BITUTHENE, BITUSTIK, PREPRUFE, and HYDRODUCT are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2020 GCP Applied Technologies Inc. All rights reserved.

© Copyright 2026 Saint-Gobain Construction Chemicals UK Limited. All rights reserved. This document is only current as of the last updated date stated below and is valid only for use in the United Kingdom. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.uk. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-05-13

https://gcpat.uk/en-gb/solutions/products/bituthene-post-applied-waterproofing/bituthene-8000-8000s-membranes