BITUTHENE® 4000 / 4000S membranes

Self-adhesive, cross-laminated HDPE waterproofing membrane with enhanced bonding characteristics

Product Description

BITUTHENE® 4000/4000S is a flexible waterproof membrane combining a high performance cross laminated, HDPE carrier film with a unique super sticky self-adhesive rubber bitumen compound.

Advantages

- Cold applied - fast, safe and simple application to substrates especially at low temperatures and saves application time.

- Suitable for application to “green” concrete - reduces programme schedules.

- Moisture tolerant primer system - allows application in damp or marginal weather conditions.

- Wide application temperature range - excellent bond to self and substrate from -5°C to +35°C.

- Twin seal laps - adhesive and film sealing provides enhanced bond and additional security.

- Cross laminated high density polyethylene carrier film - provides high tear strength, puncture and impact resistance

- Pre-marked overlaps - ensures quality of the overlaps and saves application time

- Gas resistance - contributes to methane, carbon dioxide and radon gas protection according to BS 8485 (see section 7.2.4), BRE Reports 211 (radon) and 212 (methane and carbon dioxide). Independent test reports available upon request.

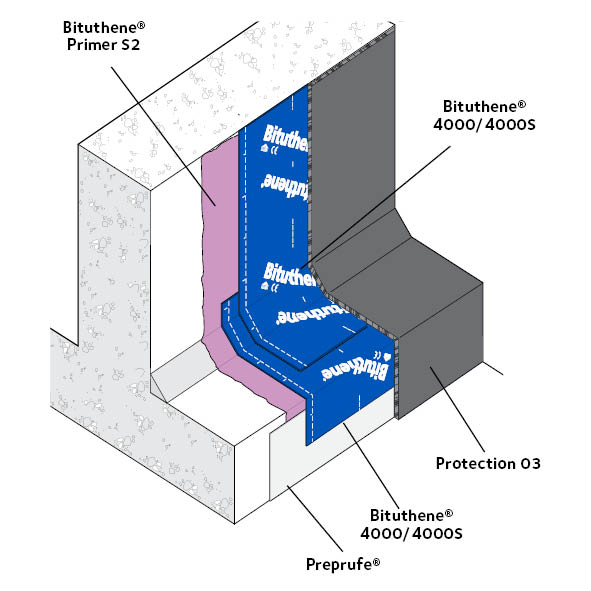

Installation

At air temperatures below +5°C measures should be taken to ensure that all surfaces are free from ice or frost. All surfaces except those below ground bearing slabs and Preprufe® R membranes should be primed with one coat of GCP’s solvent based quick drying, damp and green concrete tolerant, rubberised primer BITUTHENE® Primer S2. Primer S2 can be applied by brush or roller. Primer S2 is pink in colour to ensure proper coverage, to aid identification and to avoid substitution of proper recommended primer.

BITUTHENE® 4000/4000S membrane shall be laid by peeling back the protective release paper and applying the adhesive face onto the prepared surface, free from ice, frost, condensation or any contaminants which could adversely effect adhesion. Once the membrane is applied, cover with a protection board as soon as possible. On “green” concrete or damp surfaces, cover the membrane immediately. BITUTHENE® LM to be applied at all internal and external corners, penetrations etc. prior to applying the overall membrane.

BITUTHENE® 4000/4000S membrane should be brushed onto the surface to ensure good initial bond and exclude air. Adjacent rolls are aligned and overlapped 50 mm minimum at side and ends and well rolled with a firm pressure, using a lap roller to ensure complete adhesion and continuity between the layers. On high walls it may be necessary to batten fix the membrane to prevent slippage.

Repairs, Protection & Drainage

- Damaged areas to be repaired with an oversize patch applied to a clean dry surface extending 100 mm beyond damage and firmly rolled.

- Protect BITUTHENE® membranes immediately after application to avoid damage from other trades, construction materials or backfill, using only Protection 03 boards.

- If the area around the substructure can be drained to a low level outlet then GCP recommends the HYDRODUCT® range of drainage membranes.

Performance

BITUTHENE® 4000/4000S membrane complies with the following national standards: BS 8102: 2009, The Building Regulations (as amended) (England and Wales) 2000, The Building Regulations (Northern Ireland) 2000 (as amended), Building Standards (Scotland) Regulations 2004 (as amended).

Health and Safety

There is no legal requirement for a Safety Data Sheet for ADCOR® 500S, ADCOR® 550MI, BITUTHENE® 4000/4000S, Protection 03 board, BITUSTIK™ or HYDRODUCT®. For BITUTHENE® Primer S2 and BITUTHENE® LM read the product label and Safety Data Sheet (SDS) before use. Users must comply with all risk and safety phrases. SDS’s can be obtained from GCP Applied Technologies or from our web site at gcpat.com.

| SUPPLY | |

|---|---|

| BITUTHENE® 4000/4000S | 1 m x 20 m roll (20 sq m) Weight 36 kg |

| Storage | Store upright in dry conditions below +30°C |

| BITUTHENE® Primer S2 | 5 & 25 litre can |

| Coverage | 9-11 sq m per litre application, (depending on surface porosity and ambient temperature) |

| Ancillary Products | |

| BITUTHENE® LM | 5.7 litre packs |

| Protection® 03 board | 3 mm x 0.9 m x 2.03 m (± 6%) |

| ADCOR® 500S | 6 x 5 m rolls |

| ADCOR® 550MI | 8 x 5 m rolls |

| BITUSTIK™ 4000 | 150 mm x 12 m roll |

| Pak Adhesive | 5 litre can |

| HYDRODUCT® | Refer to HYDRODUCT® Vertical Drainage Sheets datasheet |

Equipment by Others: Lap Roller

Note: As per specification and/or local site requirements a low VOC, water-based primer BITUTHENE® Primer W2 can be used as an alternative to BITUTHENE® Primer S2.

Specification Clause

Refer to NBS Clause 180 and 190

| PHYSICAL PROPERTIES | |||

|---|---|---|---|

| Property | 4000 | 4000S | Test Method |

| Colour | Dark grey-black | Dark grey-black | |

| Application Temp. | -5°C to +20°C | +15°C to +35°C | |

| Resistance to hydrostatic head | >70 m of water | >70 m of water | ASTM D5385 |

| Declared values according to EN 13967 | |||||||

|---|---|---|---|---|---|---|---|

| Property | Declared Value | Test Method | Property | Declared Value | Test Method | ||

| BITUTHENE® | 4000 | 4000S | BITUTHENE® | 4000 | 4000S | ||

| Visible defects - MDV | None | None | EN 1850-2 | Joint strength (N/50mm) - MLV | ≥ 150 | ≥ 150 | EN 12317-2 |

| Straightness - MDV | Pass | Pass | EN 1848-2 | Water vapour transmission (μ= sD/d) - MDV |

110.000 ± 30% | 140.000 ± 30% | EN 1931 Method B |

| Length (m) - MDV | 20.15 ± 0.15 | 20.15 ± 0.15 | EN 1848-2 | Durability of water tightness against ageing/degradation (at 60 kPa) | Pass | Pass | EN 1296 EN 1928 Method B |

| Thickness (mm) - MDV | 1.52 ± 0.08 | 1.52 ± 0.08 | EN 1849-2 | Durability of water tightness against chemicals (at 60 kPa) | Pass | Pass | EN 1847 Method B EN 1928 Method B |

| Width Carrier Sheet (m) - MDV | 0.987 ±0.007 | 0.987 ±0.007 | EN 1848-2 | Durability of tensile properties against chemicals | Pass | Pass | EN13967 Annex C |

| Width Overall (roll) (m) - MDV | 1.000 ± 0.005 | 1.000 ± 0.005 | EN 1848-2 | Compatibility with bitumen | Pass | Pass | EN 1548 |

| Mass per unit area (g/m²) - MDV | 1490 ± 90 | 1550 ± 90 | EN 1849-2 | Resistance to static loading | ≥ 20 - Pass | ≥ 20 - Pass | EN 12730 |

| Water tightness to liquid water (at 60 kPa) | Pass | Pass | EN 1928 | Tensile properties - unreinforced sheets (N/50mm) - MLV | Long¹ ≥ 200 Trans² ≥ 240 |

Long¹ ≥ 200 Trans² ≥ 240 |

EN 12311-2 Method A |

| Resistance to impact (Al-board (mm) - MLV) | ≥ 150 | ≥ 150 | EN 12691 | Tensile properties - unreinforced sheets (Elongation %) - MLV | Long¹ ≥ 270 Trans² ≥ 220 |

Long¹ ≥ 270 Trans² ≥ 220 |

EN 12311-2 Method A |

| Resistance to tearing (Nail Shank)- unreinforced sheets (N) - MLV | ≥ 120 | ≥ 120 | EN 12310-1 | Reaction to fire (Class; test conditions) |

E | E | EN 13501-1 |

Footnotes:

1. Longitudinal - related to the roll direction

2. Transversal - related to the roll direction

3. MDV: Manufacturer Declared Value

4. MLV: Manufactured Limiting Value

5. NPD: No Performance Declared. All declared values shown in this data sheet are based on test results determined under laboratory conditions and with the product sample taken directly from stock in its original packing without any alteration or modification of its component parts.

gcpat.uk | United Kingdom customer service: +44 (0) 1480 478421

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

ADCOR, BITUTHENE, BITUSTIK, and HYDRODUCT are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2018 GCP Applied Technologies Inc. All rights reserved.

© Copyright 2026 Saint-Gobain Construction Chemicals UK Limited. All rights reserved. This document is only current as of the last updated date stated below and is valid only for use in the United Kingdom. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.uk. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-05-13

https://gcpat.uk/en-gb/solutions/products/bituthene-post-applied-waterproofing/bituthene-4000-4000s-membranes