BETEC® Wind UHS

High strength grout with strength class C100/115

Product Description

BETEC® Wind UHS is a cement based, volume stable grout with high initial and final strength development with final strength class of C100/115 and tested fatigue resistance according to Model Code 2010, and EN 1992-2, part 2 concrete bridges. BETEC® Wind UHS stands out by controlled volume expansion and offers maximum durability and applicability.

Advantages

- High early- and final strength development to strength class C100/115 for the most durable and reliable structural connections, statically and dynamically load bearing.

- S-N curves according to Model Code 2010 and EN 1992-2, part 2 concrete bridges can be used for de-sign without restrictions.

- High surface load capacity guarantees long-term maintenance-free constructions

- Extended workability times and exceptional rheology are ensuring fast, easy and cost effective application even with pumps.

- Compact mortar matrix due to self-compacting and controlled volume expansion.

- Declaration of performance according to EN 1504-6

- Certified according DAfStb guideline grouting concrete

- Freeze-thaw-resistant according to CIF-Method (exposure class XF4)

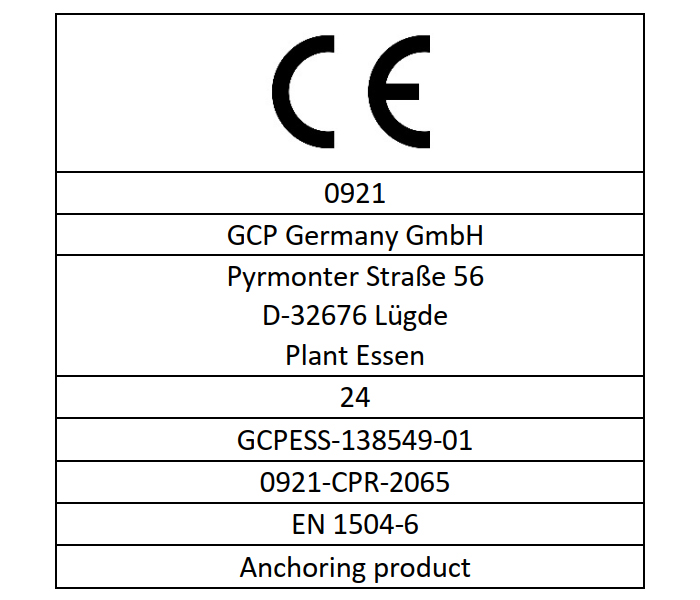

Certification

- Certificate of compliance according to DAfStbguideline. „Production and application of cement-based grouting concrete and mortars“

- Declaration of performance according to EN 1504 part 6 / System 2+

- Assessment for fatigue strength according to Model Code 2010 and EN 1992-2, part 2 concrete parts.

Areas of Application

All grouting applications where superior applicability, high performance and durable connections are required:

- Structural connections of onshore wind turbine foundations.

- Segment assembly for concrete wind towers.

Product Properties

Technical Data/Properties(1)

| BETEC® Wind UHS | ||

| Property | Unit | Value(1) |

| Grain size | [mm] | 0-1 |

| Application thickness | [mm] | 5-150 |

| Consistency | [-] | High flowable |

| Flowability | [mm] | f3 (≥ 750) |

| Correlation between flow value and slump flow(5) | [-] | 2.2 : 1.0 |

| Water addition according to required consistency and/or temperature conditions | [l /25 kg] | 2.6 |

| Workability time | [min] | approx. 90 |

| Application temperature(4) | [°C] | +5 to +35 |

| Shrinkage (91 days) | [‰] | ≤ 0.6 (SKVM0) |

| Expansion | [Vol-%] | ≥ 0.1 |

| Fresh mortar density | [kg/dm3] | ca. 2.34 |

| Yield (25kg bag) | [dm3] | ca. 11.8 |

| Calculation quantity | [kg/m3] | 2100 |

| Strength development (4) | [-] [MPa] | fast ≥ 40 |

| Compressive strength (2),(6) - 24 h - 7 d - 28 d | [MPa] | ≥ 90 ≥ 115 ≥ 145 |

| Compressive strength class | [ - ] | C 100/115 |

| Modulus of elasticity | [MPa] | approx. 45,400 |

| Exposure classes (4) | [ - ] | X0, XC1-XC4, XD1-XD3, XS1-XS3, XA1, XF1-XF4 |

| Moisture classes (4) | [ - ] | WO,WF,WA |

| Shelf life | 12 months To be stored in dry and frost-free conditions in originally sealed packaging. | |

| Packaging | Bags of 25 kg with plastic liner. 40 bags per pallet (1000 kg) | |

| Appearance | Grey powder | |

(1) Typical values from internal quality control. All tests were conducted under laboratory conditions (21°C and 65% relative humidity).

(2) The compressive strength values presented refer to prism specimens prepared in accordance with DIN EN 196-1.The conversion factor between prism specimens (DIN EN 196-1) and 150 mm cube specimens is 0.9:1.

(3) Exposure classes in accordance with DIN EN 206:2021-06/ DIN 1045-2:2023-08.

(4) Temperature conditions refer to material, mixing water, equipment, and ambient temperature. Fresh mortar temperature may vary.

(5) Slump flow determined according to Section C.2.2 “Consistency of fresh mortar (slump flow)” of Annex C, DAfStb Guideline for Grout Concrete.

(6) At +5 °C (material, water, ambient), the product reaches a compressive strength of 5 MPa after approx. 24 hours.

Application

1 Preparation of Substrate

- Substrate preparation has to be according EN 1504-10 section 7.

- The substrate has to be free from dirt, grease, laitance, loose concrete, loose particles or layers which could adversely affect adhesion.

- Remove all damaged concrete and prepare substrate by sand or grid blasting, high pressure water jetting, or other methods until base concrete is exposed, offering sufficient roughness (bond) and open pores.

- The substrate must be pre-wetted with clean water until saturated. The substrate should be damp, but without free standing water.

- The substrate must be frost-free and have a cohesion of minimum 1.5 MPa.

2 Mixing

- It is advised to mix the product by suitable mechanical compulsory mixers.

Mechanical

- Add the total required quantity of water into the mixer, add the powder and mix for 5 minutes until a lump-free, homogeneous mixture is obtained.

- Recommendations can be made for the selection of a suitable forced action mixer and feed pump.

- Mixing pumps (continuous mixers) are not recommended for mixing the product but can be used as a feed pump.

Manual

- The product has to be mixed using a suitable manual forced action mixer (400-600 rpm) (two-paddle mixers recommended). The mixing head must be completely immersed in the powder.

- Add the total required quantity of water into the mixer, add the powder and mix for 5 minutes until a lump-free, homogeneous mixture is obtained. Never use more than the maximum water quantity.

- The mixture must be allowed to rest to release air entrapped during mixing.

- Once the grout has deaerated, apply immediately. Do not prepare more material than can be used within the open time of the material.

- When the grout starts to set, remix for 1 minute but never add more water.

3 Application

- The material is always poured or pumped from one side or corner in one continuous application. A dense and non-absorbent formwork is necessary. To prevent air entrapment, sufficient ventilation holes must be provided.

- Do not vibrate.

4 Curing

- After treatment has to be according EN 13670

- In warm or windy conditions protect the applied material from dehydration by mist-spraying with clean water or protective tarpaulins until the initial set has taken place.

- In cold conditions cover with insulated tarpaulin, polystyrene or other insulating material. Protect surfaces against frost and rain until final set has taken place.

- In cold, humid or unventilated areas it can be necessary to allow for a longer curing period, or to introduce forced air movement to avoid condensation. Never use dehumidifiers during the curing period or within 28 days after application.

- Formwork should not be removed for at least 48 hours.

- The after-treatment should be at least 5 days.

- The after-treatment should take place as soon as possible, at the latest when the material surface starts to set.

- As an alternative to the conventional treatment methods, suitable curing agents can be used to prevent rapid water loss.

5 Cleaning and maintenance

- Mixing and application equipment should be cleaned immediately with clean water. Hardened material needs to be removed mechanically.

6 Special remarks

- Cementitious materials can lead to incompatibilities under certain conditions in combination with non-ferrous metals (such as aluminium, copper, zinc).

- Low temperatures reduce flow and delay the early strength development. High temperatures accelerate the strength development and decrease the open time of the material.

- Depending on geometry and application thickness, reinforcement steel can be necessary.

- Lateral grouting overhang should be kept as low as possible (approx. 20-50mm).

Health & Safety

BETEC® Wind UHS is a product based on cement and can therefore cause burns to skin and eyes, which should be protected during use. Wear gloves and protective eye shields. Wearing a dust mask is advised. Treat splashes to eyes and skin immediately with clean water. Consult a doctor when irritation continues. If accidentally ingested, drink water and consult a doctor. Users must comply with all risk and safety phrases. MSDS’s can be obtained from GCP Germany GmbH. GISCODE ZP1.

Certificate CE

BETEC® Wind V

www.gcpat.com

For technical information:

GCP Germany GmbH

Alte Bottroper Straße 64

45356 Essen

T. +49 (0) 201 86147-0

F. +49 (0) 201 619475

E. info.betec@gcpat.com

gcpat.uk | United Kingdom customer service: +44 (0) 1480 478421

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation, and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right

Betec® is a trademark, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2025 GCP Applied Technologies Inc. All rights reserved.

Printed in Germany | 07/2024 | Data Sheet Nr. 1.54 RV 0

© Copyright 2026 Saint-Gobain Construction Chemicals UK Limited. All rights reserved. This document is only current as of the last updated date stated below and is valid only for use in the United Kingdom. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.uk. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-10-27

https://gcpat.uk/en-gb/solutions/products/betec-grouts-and-cementitious-mortars/betec-wind-uhs