BITUTHENE® LM (E) (UK/IE Version)

Two-component elastomeric liquid applied detailing compound for use with GCP Applied Technologies waterproof membranes

Product Applications

BITUTHENE ® LM (E) detailing compound is designed to complement GCP sheet membranes and systems. BITUTHENE® LM (E) detailing compound is designed to be used where liquid applied waterproofing is needed to as part of a system designed to provide system watertight continuity. BITUTHENE® LM (E) is a bitumen modified polyurethane sealant that cures to form a tough seamless rubber-like waterproof layer.

Details shown are typical illustrations only and not working drawings. For assistance with working drawings and additional technical advice please contact GCP Technical Services.

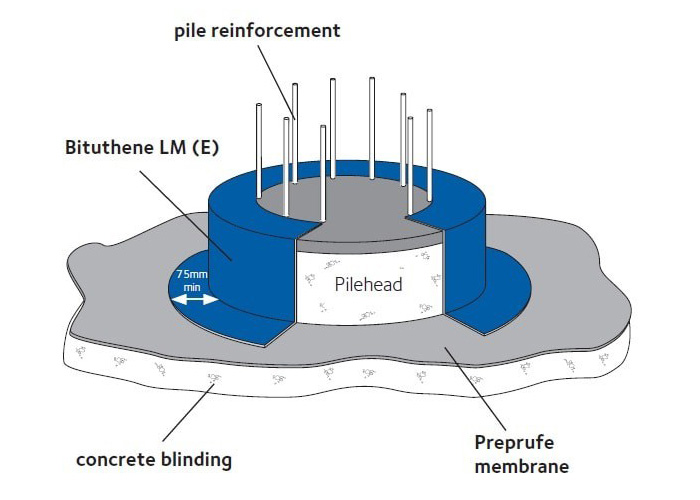

Typical details suitable for BITUTHENE® LM (E) liquid membrane:

- Pile head terminations

- Terminations into DPC

- Pipe and rod penetrations

- Membrane continuity through masonry

- Internal and external corners

Advantages

- Liquid applied – conforms to irregular profiles

- Waterproof – resistant to water vapour and water pressure

- Tough rubber-like - flexible and damage resistant

- Seamless – joint free membrane

- Chemical cure – The two parts of BITUTHENE® LM (E) liquid membrane are mixed on site and troweled on to provide a simple and quick waterproofing and detailing aid in conjunction with BITUTHENE® and PREPRUFE® sheet membrane waterproofing systems.

- Cold applied – no hazardous flame required

- PREPRUFE® and BITUTHENE® membrane compatible – complements both waterproofing systems

This document is applicable to projects and applications in the UK only. Please refer to the local website for further information at gcpat.uk, or contact your GCP representative.

System Components

Detailing Compound:

BITUTHENE® LM (E)—Part A and Part B: two component detailing compound designed for use with GCP products. When cured BITUTHENE® LM (E) forms a form a tough seamless rubber-like waterproofing for penetrations, laps, and other critical detail areas

Ancillary/Companion Products used with BITUTHENE® LM (E):

- BITUTHENE® and PREPRUFE®, Membranes as detailed on GCP published application guides, data sheets and drawings.

Limitations of Use

- BITUTHENE® LM (E) detailing compound is not intended for any other use, other than those specifically detailed in this data sheet or any supplementary product literature found at gcpat.uk. For any use not mentioned within this data sheet, contact GCP Technical Services for guidance. Contact GCP Technical Services where any other use is anticipated or intended.

- BITUTHENE® LM (E) detailing compound is designed where in-service temperatures will not exceed 54°C (130°F).

- BITUTHENE® LM (E) detailing compound is not designed for permanently exposed application and should be covered preferably within 30 days of application.

Note that because of local regulations, test standards and customs, product literature and offerings may be different in various locations. If you have any questions or comments, please contact your local customer service at info-gb@gcpat.com or +44 (0) 1480 478421.

Safety and Handling Information

Users must read and understand the product label and safety data sheet (SDS) for each system component. All users should acquaint themselves with this information prior to working with the products and follow the precautionary statements. SDSs can be obtained by contacting your local GCP representative or office, by calling GCP toll free at +44 (0) 1480 478421 and in some cases from our web site at gcpat.uk.

Storage

- All products must be handled and stored consistent with BITUTHENE® LM (E) detailing compound methods statement

- All BITUTHENE® LM (E) detailing compound product should be stored upright in its original container

- Product Shelf Life: 1 year from date of manufacture.

- Store in dry conditions between +10°C and 45°C

- Store off ground, under tarps or otherwise protected from rain and ground moisture.

Installation

Technical Support, Details and Technical Letters

The most up to date detail drawings and technical letters are available at gcpat.uk For complete application instructions, please refer to the current GCP Applied Technologies Contractor Handbook and Literature on (www.gcpat.uk). Documents in hardcopy as well as information found on websites other than www.gcpat.uk may be out of date or in error. Before using this product, it is important that information be confirmed by accessing www.gcpat.uk and reviewing the most recent product information, including without limitation product data sheets and contractor manuals, technical bulletins, detail drawings and detailing recommendations. Please review all materials prior to installation of BITUTHENE® LM (E) liquid membrane. For technical assistance with detailing and problem solving please contact your local GCP representative or office, by calling GCP toll free at +44 (0) 1480 478421.

Temperature

Only apply BITUTHENE® LM (E) liquid membrane in dry weather and when air temperatures are between 5°C and 40°C.

Substrate Preparation

Surfaces shall be dry and free from dust, dirt, grease or other contaminants. Ambient temperature shall be +5°C and rising. BITUTHENE® LM (E) liquid membrane application should be sequenced as detailed in any drawings or installation instructions for BITUTHENE® and PREPRUFE® waterproofing membranes.

- BITUTHENE® LM (E) liquid membrane may be used as a pointing surface sealer.

- A minimum overlap of the BITUTHENE® sheet membrane of 50 mm shall be provided and where applicable between 50 mm and 75 mm onto PREPRUFE® sheet membranes .

- BITUTHENE® LM (E) liquid membrane is designed to adhere to clean, dry concrete and metal substrates.

Mixing

BITUTHENE® LM (E) liquid membrane pack is supplied in a single can containing Part A base with the Part B reactor located separately under the can lid. Using a slow speed mixer with Paddle MR2, pre-mix part A then, add Part B (clear) to Part A (black). Mix the two parts for approximately 1 minute at 100 rpm. Mix for a further 2-3 minutes at 200-300 rpm until uniform blending is achieved. Scrape the sides and bottom of the container during mixing to ensure thorough blending. At ambient temperatures below +10°C, store overnight at +20°C to improve blending and workability. Clean tools and equipment with solvent tool cleaner before BITUTHENE® LM (E) liquid membrane has cured.

Application

Apply BITUTHENE® LM (E) liquid membrane with a trowel or float, solid barrel gun or hand held squeegee to achieve a minimum thickness of 2.5 mm. Once mixed BITUTHENE® LM (E) liquid membrane must be applied within one hour at normal ambient temperatures. Material which has thickened must be discarded.

BITUTHENE® LM (E) liquid membrane shall be allowed to cure for 24 hours before being overlapped by BITUTHENE® or PREPRUFE® Membranes.

UV Protection

BITUTHENE® LM (E) liquid membrane is not designed for permanently exposed applications and should be covered preferably within 30 days of application.

| SUPPLY | |

|---|---|

| BITUTHENE® LM (E) | 5.7 litre pack (Parts A & B) |

| Shelf Life | 12 months |

| Complementary Product | |

| ADCOR® 500S (waterstop) | 6 ea x 5m rolls |

| Ancillary Equipment | |

| Megamixer variable speed 100 - 500 rpm (1200 W 110v by Refina or similar). Solid barrel gun, spatula, trowel or float. | |

| Approximate Coverage | BITUTHENE® LM (E) 5.7 litre (Part A & B) |

| 2.5 mm thick x 300 mm wide | 7.6 linear m (2.28 m2/unit) |

| 2.5 mm thick x 2 x 150 mm wide with 20 mm Fillet | 6.0 linear m |

| 20 mm Fillet | 28.4 linear m |

Coverage rates will be dependent on substrate texture.

NBS Specification Clause

Refer to Clause J40 370.

gcpat.uk | United Kingdom customer service: +44 (0) 1480 478421

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

BITUTHENE is a trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2020 GCP Applied Technologies Inc. All rights reserved.

© Copyright 2026 Saint-Gobain Construction Chemicals UK Limited. All rights reserved. This document is only current as of the last updated date stated below and is valid only for use in the United Kingdom. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.uk. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-05-13

https://gcpat.uk/en-gb/solutions/products/bituthene-post-applied-waterproofing/bituthene-lm-e