SILCOR® Primer EPS

Two component, epoxy primer for dry to moist substrates with extended pot life for hot weather applications.

Product Description

SILCOR® Primer EPS is a two component epoxy primer specifically formulated for application in hot weather conditions such as tropical countries or in summer.

Silcor Primer EPS cures in conditions of high relative humidity and the pot life and the reaction at 35ºC is similar to the pot life and the recoat time of a standard epoxy primer at 20ºC. All components are pre-weighted in an easy to mix system:

- A-component : epoxy resin.

- B-component : polyamine hardener

Principal Applications

- Epoxy primer suitable for dry to moist substrates with extended pot life for hot weather applications prior to the application of elastomeric coatings and epoxy systems.

- Slow epoxy primer for dry to moist substrates prior to the application of elastomeric coatings and epoxy systems in normal conditions.

Installation

1. Surface Preparation

- The concrete surface can be moist with a maximum moisture content of 10% before application of the primer. Prior to the application of the SILCOR® waterproofing membrane, the surface moisture content of the primer must be no more than 5%.

- The surface needs to be clean and sound.

- The surface must be free of dust, laitance, sealers, grease or any other contaminants that might influence bonding of the resin. Sand blasting is recommended. Clean dust by hovering. In case of using high pressure water jet, allow sufficient time for the residual humidity to dissipate.

2. Mixing

- Store Silcor Primer EPS in a dry and cool spot out of direct sunlight. Storing the product in direct sunlight will heat up the components and reduce pot life considerably.

- Add the complete B-component to the A-component to assure correct mixing ratio.

- Mix with a slow turning mixer (less than 300 rpm) for 3 minutes in order to obtain a homogenous mixture.

- Mixing temperatures should preferably be between 10°C and 40°C. Higher temperatures reduce the pot life considerably.

3. Application

- Application temperatures must be between 10°C and 40°C.

- The primer needs to be applied to the surface immediately after a set is mixed.

- Pour the primer onto the surface in a zigzag trail.

- After pouring onto the surface, the primer is evenly distributed onto the surface with foam rubber squeegees and rolled into the surface, within the pot life, using Perlon rollers.

- The primer needs to be evenly distributed with complete coverage of the surface.

- If the surface is very porous and absorbs primer leaving an open surface (matt aspect), additional primer needs to be added in this area within the pot life or recoat time of the primer.

- Primers are always applied in 2 layers in criss-cross fashion.

- In case of spray application, the first layer is always rolled into the surface to obtain good pore coverage and adhesion.

- Design consumption: 350 g/m2 but can be influenced by the surface roughness.

4. Curing

The recoat window of the primer is influenced by ambient temperature and humidity.

Recoat window

- Application of Silcor elastomeric membranes: 12 to 24 hours.

- When the recoat window time is exceeded before the first coat of the membrane is applied, grind slightly the primer and re-apply a new layer of Silcor Primer EPS.

- The recoat window of Silcor Primer EPS can be extended by broadcasting dry quartz sand into the primed surface. Broadcast sand to full saturation. Use sand of 0.4-0.8 mm grain size for coating thicknesses up to 2 mm. For larger coating thicknesses larger grain sizes can be used. Remove the surplus of sand after the primer is hand dry with a scrubber to remove all loose and partially bonded particles.

5. Cleaning and Maintenace

- Mixing and application equipment should be cleaned immediately with solvent MEK. Remove hardened material mechanically.

Advantages

- Adjusted pot life and curing for hot and tropical weather applications.

- Excellent adhesion: exceeds concrete coherence.

- Can be applied to moist substrates with a maximum moisture content up to 10%.

- Easy to use multi-purpose primer.

- Easy to apply by roller or brush.

Supply

| Unit of Sale | |

|---|---|

| Silcor Primer EPS Part A | 5.5 kg |

| Silcor Primer EPF Part B | 4.5 kg |

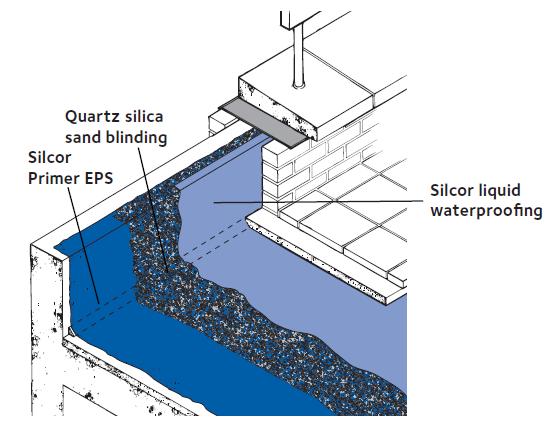

Details shown are typical illustrations only and not working drawings. For assistance with working drawings and additional technical advice please contact GCP Technical Services.

Typical Properties

| Property | Typical Value |

|---|---|

| Adhesion to concrete | surpasses concrete coherence |

| Density | 1.05 kg/dm3 |

|

Viscosity (mixture) |

Approx. 1000 mPas |

|

Pot Life (250 g) |

Approx. 120 min |

|

Touch dry time |

Approx. 7 hours |

|

Recoat window |

12 to 24 hours |

| Full cure | 7 days |

| Minimum application temperature | 10°C |

All declared values shown in this data sheet are based on test results determined under laboratory conditions and with the product sample taken directly from stock in its original packing without any alteration or modification of its component parts.

Consumption

Has to be estimated by the engineer or operator and depends on the surface texture.

Design consumption: 350 g/m², depending on the absorption and roughness of the surface.

Storage

Silcor Primer EPS should be stored under cover protected from direct sunlight. Protect from moisture and frost. Rotate the product in order not to exceed its shelf life. Shelf life: 2 years.

Warranties

GCP and trained contractors can provide warranties for individual projects. Contact GCP for further details.

Health and Safety

Read the product label and Safety Data Sheet (SDS) before use. Users must comply with all risk and safety phrases. SDSs can be obtained from gcpat.com.

gcpat.uk | United Kingdom customer service: +44 (0) 1480 478421

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

SILCOR is a trademark, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2016 GCP Applied Technologies Inc. All rights reserved.

© Copyright 2026 Saint-Gobain Construction Chemicals UK Limited. All rights reserved. This document is only current as of the last updated date stated below and is valid only for use in the United Kingdom. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.uk. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-05-13

https://gcpat.uk/en-gb/solutions/products/silcor-primer-eps