SERVIRUFE® Traffic Deck System

Cold-applied, concrete deck waterproofing system combining sheet and liquid membranes

System Description

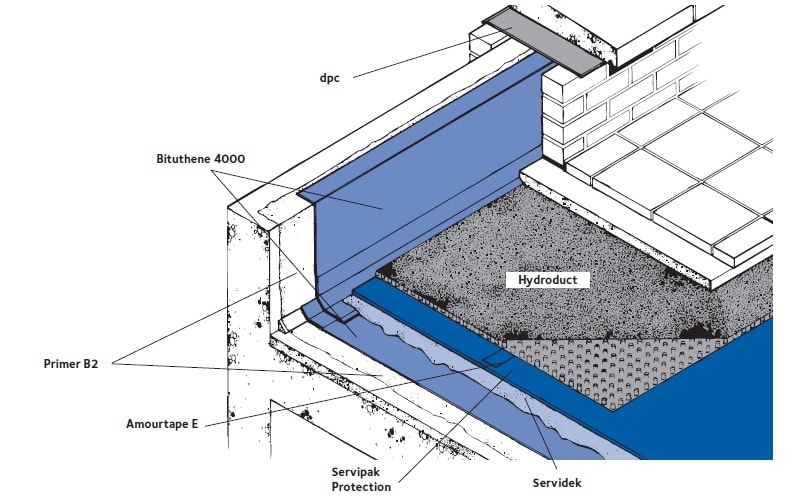

SERVIRUFE® Traffic Deck System combines BITUTHENE® 4000 sheet membrane and SERVIDEK® liquid membrane with SERVIPAK® protection boards to provide a durable waterproofing and protection system capable of accepting a wide variety of wearing surfaces on concrete decks subject to pedestrian and vehicular traffic.

Unlike hot applied systems which can become brittle and debond from the substrate, SERVIRUFE® Traffic Deck System remains flexible and fully bonded.

The system can be further enhanced by using HYDRODUCT® as a sub-surface drainage sheet.

SERVIRUFE® Traffic Deck with Drainage Option

Product Advantages

- Dual Protection System - combines the advantages of preformed sheet with seamless liquid for maximum assurance

- Robust protection - SERVIPAK® boards prevent damage during construction and service

- No naked flame system - eliminates fire hazard

- Flexible - membrane and compound properties accommodate minor movement

- Bonded system - prevents lateral water migration and transfers braking forces to substrate

- Optional drainage system - high compressive strength drainage sheet available to provide efficient deck drainage.

Installation

Surface Preparation

Substrate surfaces must be dry, clean, and free from sharp projections such as nail heads, concrete nibs, etc. Concrete surfaces should have a float finish. All surfaces to be waterproofed should be first treated with B2 primer, at a coverage rate of 10 - 12 m2 per litre and allowed to dry completely.

Application

- Release paper on BITUTHENE® 4000 membrane is removed prior to application to the substrate. In all cases, as the membrane is laid, it must be pressed firmly from the middle outwards so that air is not trapped.

- Adjacent membrane sheets should be overlapped by at least 100 mm along their length and by at least 100 mm at ends and vertical joints.

- All lap joints must be pressed firmly to form a continuous bond ensuring weathertightness.

- Parts A and B of SERVIDEK® compound are mixed on site to a combined volume of 22.5 litres and spread by a trowel or squeegee onto the membrane at a coverage rate of approximately 10 m2 per unit. Application of SERVIDEK® compound must take place immediately, otherwise pouring and spreading will be restricted.

- Application of SERVIDEK® compound should not be made if rain or frost are imminent, or in conditions where it is likely to freeze before curing.

- SERVIDEK® compound should be protected immediately from solar heat gain by bedding Servipak 3 protection boards onto the uncured compound.

- SERVIPAK® 3 protection boards should be cut and trimmed on site and joints closely butted. Joints between the boards are covered with Armourtape bonded onto primed surface of SERVIPAK® 3 boards.

For taping joints below cold applied finishes use Perm-A-Barrier Detail Membrane. See separate data sheet. - Any exposed vertical surfaces of BITUTHENE® 4000 membrane should be adequately protected by Solarshield or a suitable counter flashing.

- A suitable surfacing of hot-rolled asphalt or concrete must be applied over the SERVIPAK® 3 protection boards.

Supply

| SERVIRUFE® Traffic Deck System | |

|---|---|

| Length | 1.0 m x 20.0 m roll (20 sq m) |

| Weight | 32 kg |

| Palletisation | 15 rolls per pallet |

| Storage | Store upright in dry conditions below +30°C. |

| Primer B2 | 5 and 25 litre drums |

| Coverage | 10-12 sq metres per litre depending on method of application, surface texture, porosity and ambient temperature |

| SERVIDEK® | 22.5 litre pack |

| Coverage | Approx. 12.5 sq metres per mixed unit @ 1.5 mm thickness |

| Storage | Under cover in original sealed containers above +4°C, below +30°C |

| Shelf Life | 12 months |

| Working life | Approximately 20 minutes at 20°C RH 60% |

| Protection Boards | |

| SERVIPAK® 3 | 3 mm x 1.0 m x 2.0 m |

| SERVIPAK® 6 | 6 mm x 1.0 m x 2.0 m |

| Armourtape E | 75 mm x 20 m rolls |

| HYDRODUCT® 650 | 32 m x 1.25 m = 40 m2 |

| Ancillary Materials | See separate data sheets |

Equipment by Others: Brush or airline for cleaning surface. Soft broom, paint brush or roller, Stanley knife and hand tools.

Health and Safety

For SERVIDEK®, Primer B2, BITUTHENE® Liquid Membrane read the product label and Safety Data Sheet (SDS) before use. Users must comply with all risk and safety phrases. SDSs can be obtained from GCP Applied Technologies or gcpat.com.

There is no legal requirement for a Safety Data Sheet for BITUTHENE® 4000, SERVIPAK® Protection Boards, Armourtape, HYDRODUCT®. For health and safety questions on these products please contact GCP Applied Technologies.

Specification

For NBS specifications contact GCP Applied Technologies.

gcpat.uk | United Kingdom customer service: +44 (0) 1480 478421

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

SERVIRUFE is a trademark, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2016 GCP Applied Technologies Inc. All rights reserved.

© Copyright 2026 Saint-Gobain Construction Chemicals UK Limited. All rights reserved. This document is only current as of the last updated date stated below and is valid only for use in the United Kingdom. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.uk. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-05-13

https://gcpat.uk/en-gb/solutions/products/liquid-waterproofing/servirufe-traffic-deck-system