GGM Gasvoid PF/FF

High strength gas venting composites for use beneath GCP gas membranes as part of a passive gas ventilation system

Product Description

GGM Gasvoid is a high strength, preformed geocomposite designed specifically to remove harmful gases from beneath gas membrane systems. Gasvoid consists of a HDPE (high density polyethylene) cuspated core hot welded to a geotextile filter.

GGM Gasvoid FF Venting Blanket

A high strength, preformed gas venting composite designed for use where full footprint (FF) gas venting is required beneath structures.

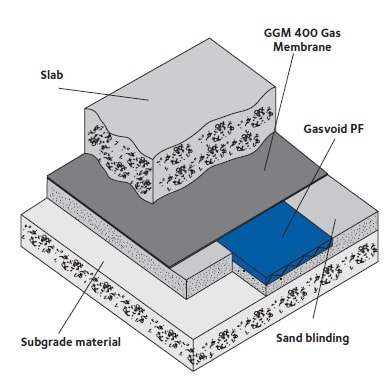

GGM Gasvoid PF Venting Blanket

A high strength, preformed gas venting composite designed for use where partial footprint (PF) gas venting is required beneath structures.

System Components

Designed to link with GCP Gas Venting kits - see separate datasheets.

Installation

- GGM Gasvoid is supplied in rolls which are easily manhandled.

- GGM Gasvoid is designed to be installed below the membrane with flat side of the product against the underside of the membrane.

- Carry or roll GGM Gasvoid from the storage area to place of work. DO NOT DRAG the roll, as this will damage the product. If mechanical plant is used to carry the rolls ensure that the Gasvoid is not damaged by bucket teeth, etc.

- In choosing the commencing point and direction of laying, consider the intended access point for concreting vehicles to avoid any need to traffic over the GGM Gasvoid.

- GGM Gasvoid can be cut to length with a sharp knife or disc saw and may be cut to fit around pile caps and other slab penetrations. GGM Gasvoid may also be taken under slab thickenings and around ground beams. Installation of full and partial footprint venting systems is described below

- Collected gas is discharged from the Gasvoid using standard gas venting fittings which connected directly to the Gasvoid sheet. Separate installation diagrams are supplied with gas vent fittings.

- Before concreting, gas membrane is installed on top of GGM Gasvoid.

- Steel reinforcement can be supported off the GGM Gasvoid and gas membrane by the usual spacers.

Full footprint/blanket application (GGM Gasvoid FF):

- The GGM Gasvoid FF geotextile extends beyond the width of the dimpled HDPE core at one side to create an overlap.

- Unroll the first roll of GGM Gasvoid FF and turn over to leave the geotextile flap on the side of the roll facing the area where next GGM Gasvoid FF sheet will be unrolled.

- The next roll should be placed in a similar way to the first and such that the dimpled plastic cores butt together.

- Continue laying further rolls in a similar manner to create gas venting blanket.

- When the other edge of the slab is reached, the Gasvoid roll may need to be reduced in width. Cut the excess dimpled core away and fold the textile onto the top of the Gasvoid.

Partial footprint application (GGM Gasvoid PF):

- GGM Gasvoid PF should be installed in strips at centres shown on drawings. A GGM Gasvoid PF strip can be used around the perimeter to act as a collector strip connected to gas vent outlets.

| Supply | |

|---|---|

| GGM Gasvoid PF | 915 mm x 50 m roll |

| GGM Gasvoid FF | 915 mm x 50 m roll |

BS Specification Clause

Refer to Clause J40/295. Product reference: Gasvoid PF/FF.

Health and Safety

There is no requirement for a Safety Data Sheet for GGM Gasvoid. For health and safety questions on these products please contact GCP Applied Technologies or gcpat.com.

Details shown are typical illustrations only and not working drawings. For assistance with working drawings and additional technical advice please contact GCP Technical Services.

| Physical Properties | ||

|---|---|---|

| CORE | Typical Value | Test Method |

| Type | Single Cuspated (Dimpled) | |

| Material | Gas resistant HDPE (High Density Polyethylene) | |

| Mass per unit area | 1250 g/m² | BS EN 965: 1995 |

| Impact resistance | Excellent (even at low tempertaures) | |

| Bacteria / Chemical resistance | Superior & highly resistant to all common chemicals | |

| COMPOSITE | Typical Value | Test Method |

| Intrinsic Permeability | > 1.30 x 10-5 m² | DoE |

| Forcheimer Term | < 19.0 s/m | DoE |

| Porosity | Min 0.85 | DoE |

| Thickness at 2 kPa | 27 mm | BS EN 964-1:M 1995 |

| Compressive Strength | 250 kPa | ASTM D1621 (MOD) |

| Tensile Strength (Long/ Cross) | 20 / 20 kN/m | BS EN ISO 10319: 1996 |

| Elongation (Long/ Cross) | 40 / 40 % | BS EN ISO 10319: 1996 |

| CBR Puncture Resistance | 3000 N | BS EN ISO 10319: 1996 |

| Life Expectancy | 120 years | |

| Working TemperaturE | -20°C to 80°C | |

| Chemical Resistance | Superior & excellent resistance to all common chemicals | |

| Bacteria/ Fungi | Does not support growth | |

| Compatibility with Gas Membranes | Fully compatible. The composite has a flat side in contact with the gas membrane to keep long term contact stresses to a minimum. | |

| Health, Safety, Environment | INERT. No known health hazards. No precautions necessary. | |

| GEOTEXTILE | Typical Value | Test Method |

| Type | Non woven needle punched and heat treated | |

| Material | Polypropylene | |

| Mass per unit area | 125 g/m² | BSEN 965: 1995 |

| Thickness at 2 kPa | 1.2 mm | BSEN 964-1:M 1995 |

| Tensile Strength (Long/Cross) | 9.75 / 9.75 kN/m | BSEN ISO 10319: 1996 |

| Elongation at break (Long/Cross) | 50 / 50 % | BSEN ISO 10319: 199 |

| Pore Size 090 | 115 micron | BS 6906 (2) |

| Water Flow at 50 mm | 115 l/m²/s | BS 6906 (3) |

| Permeability at 2kPa | 3.1 x 10-3 m/s | BS 6906 (3) |

| Breakthrough Head | 0 mm | BS 6906 (3) |

| Puncture Resistance | 1600 N | BSEN ISO 12236: 1996 |

| Chemical Resistance | Highly resistant to all common chemicals (including leachate) |

Footnotes:

1. The geotextile is bonded to the core to prevent intrusion into and the blocakge of the gas passageways under the action of pressure of backfill material.

2. The values given are indicative and correspopnd to nominal results obtained in our laboratories and testing institutes. The right is reserved to make changes without notice at any time.

3. Allowable tolerances are +/- 10% of the typical value.

Note: All test results shown in this data sheet are determined under laboratory conditions, using product samples taken from inventory in original packaging, without alteration or modification.

gcpat.uk | United Kingdom customer service: +44 (0) 1480 478421

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

© Copyright 2016 GCP Applied Technologies Inc. All rights reserved.

© Copyright 2026 Saint-Gobain Construction Chemicals UK Limited. All rights reserved. This document is only current as of the last updated date stated below and is valid only for use in the United Kingdom. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.uk. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-05-13

https://gcpat.uk/en-gb/solutions/products/ggm-gasvoid-pfff