BETEC® 110, 140, 180, 516

High performance grouts

Product Description

BETEC® 110, 140, 180 & 516 are cement based, shrink-compensated grouts with high initial and final strength development, superior applicability and high load bearing surface, suitable for all grouting works in the safest, most targeted and productive way.

Advantages

- High early- and final strength properties to strength class C60/75 for structural connections, static and dynamic load bearing.

- High load bearing surface for long-term maintenance free construction of foundations.

- Extended open times and exceptional rheology for a fast, easy and cost effective application by pumping or pouring.

- Freeze-thaw-resistant according to CDF-method for BETEC® 180 (exposure class XF4)

- Self-compacting and controlled volume expansion.

- Certified according DAfStb guideline and CE marked according to EN 1504-6.

Certification

- Certificate of compliance according to DAfStbguideline. „Production and application of cement-based grouting concrete and mortars“.

- CE certified according to EN 1504-6.

Field of Application

All grouting applications where superior applicability, high performance and durable connections are required:

- Assembly of precast structures.

- Grouting of bridge bearings and bridge support structures.

- Grouting foundations of machinery and industrial equipment.

- Wind turbine assembly and foundation grouting.

- Rail anchoring and underfilling in industry and MRT segments.

- Under water grouting applications.

Product Properties

Technical Data/Properties(*)

| BETEC®110 | BETEC®140 | BETEC®180 | BETEC®516 | ||

| Properties | Unit | Value1) | |||

| Grain size | [mm] | 0-1 | 0-4 | 0-8 | 0-16 |

| Application thickness | [mm] | 5 - 35 | ≥ 15 | ≥ 30 | ≥ 60 |

| Consistency | [-] | High Flowable | |||

| Flow class | [mm] | f3 (≥ 750) | f2 (650 -740) | a2 (600 – 690) | a2 (600-690) |

| Correlation between flow value and slump flow 5) | [-] | approx. 2:1 | approx. 2:1 | not relevant | not relevant |

| Maximum water quantity According to required consistency and/or temperature conditions | [l /25 kg] | 3.3 | 2.6 | 2.3 | 2.5 |

| Workability time | [min] | ≈ 90 | |||

| Application temperature 4) | [°C] | +5 to +35 | |||

| Shrinkage class | [-] | SKVM II | SKVB I | ||

| Expansion | [Vol-%] | ≈ 0.9 | |||

| Fresh mortar density | [kg/dm3] | ≈ 2.2 | ≈ 2.2 | ≈ 2.3 | ≈ 2.4 |

| Yield (25kg bags) | [l] | 12 - 13 | |||

| Calculation quantity | [kg/m3] | 1950 | 2000 | 2110 | 2190 |

| Strength development | [-] | Fast | |||

| Early strength class after 24h | [-] [MPa] | A ≥ 40 | |||

| Compressive strength 2),6) - 24 h - 28 days - 91 days | [MPa] | ≥ 40 ≥ 85 ≥ 90 | |||

| Static Modulus of Elasticity | [N/mm²] | > 34.400 | > 37.200 | >42.000 | >37.400 |

| Final strength class | [ - ] | C 60/75 | |||

| Exposure classes 3) | [ - ] | X0, XC1-XC4, XD1-XD3, XS1-XS3, XA1, XF1-XF3, XF4(4)(5)(6)7) | |||

| Moisture classes 3) | [ - ] | WO, WF, WA | |||

1) Typical values from internal quality control. All tests were conducted under laboratory conditions (21°C and 65% relative humidity).

2) The compressive strength values presented refer to prism specimens prepared in accordance with DIN EN 196-1.The conversion factor between prism specimens (DIN EN 196-1) and 150 mm cube specimens is 1:1.

3) Exposure classes in accordance with DIN EN 206:2021-06/ DIN 1045-2:2023-08.

4) Temperature conditions refer to material, mixing water, equipment, and ambient temperature. Fresh mortar temperature may vary.

5) Slump flow determined according to Section C.2.2 “Consistency of fresh mortar (slump flow)” of Annex C, DAfStb Guideline for Grout Concrete.

6) At +5 °C (material, water, ambient), the product reaches a compressive strength of 5 MPa after approx. 24 hours.

7) Exposure class XF4 verified for BETEC® 180 using CDF method.

| Shelf life | 12 Months Stored under cover, clear of the ground, protected from all sources of moisture and frost. | ||||

| Packaging | Bags of 25 kg with plastic liner. 40 bags per pallet (1000kg) | ||||

| Appearance | Grey powder | ||||

Application

1. Preparation of Substrate

- The substrate preparation must be in accordance with DIN EN 1504-10 section 7.

- The substrate must be free of dirt, grease, laitance, loose concrete, loose particles or layers that could adversely affect adhesion.

- Remove damaged concrete and prepare the substrate by sandblasting, shot blasting or, high-pressure water jetting or other methods until the grain is exposed and sufficient roughness (bonding) is achieved, and the pores are open.

- The substrate must be moistened in advance with clean water. The substrate should be damp, but without standing water. The substrate must be frost-free and have a surface tensile strength of at least 1.5 MPa.

2. Mixing

- The product has to be mixed using a suitable forced action mixer (400-600rpm). The mixing head must be completely immersed in the powder.

- Add the entire required amount of water to the mixer and mix for 5 minutes until a lump-free, homogeneous mixture is obtained.

- The amount of water can be varied to achieve the desired consistency. Never use more than the maximum permissible amount of water.

- The mixing time depends on the type of mixer and is at least 5 minutes.

- The mixture must be left to rest to release any air trapped during mixing.

- The grout should be poured into the area to be grouted as soon as possible after deaeration. Only mix as much grout as can be used within the processing time of the material.

- If the grout cannot be processed immediately, it should be briefly remixed before pouring. Never compensate for reduced flow behaviour by adding additional water.

3. Application

- The material is always poured or pumped from one side or corner in a continuous operation. If formwork is used, it should be impermeable and non-absorbent. To prevent air pockets, sufficient ventilation holes or slots should be provided.

- Due to the self-levelling properties of the grout, additional poking is not necessary. The use of vibrators is not permitted.

- When casting large areas, apply the grout using screw pumps.

4. Curing

- After treatment must be carried out in accordance with DIN EN 13670/ DIN 1045-3.

- In warm ambient conditions or when exposed to wind, the grout must be protected against drying out by covering it with foil, placing water-retaining covers on top or continuously spraying it with clean water. In cold ambient conditions, protect against moisture loss and cooling with insulating tarpaulins, insulation materials, heatable cover sheets or other insulating materials. Protect surfaces from frost and rain until final setting.

- In cold, damp or unventilated areas, it may be necessary to allow for a longer curing time or to use forced ventilation to prevent condensation. Never use dehumidifiers during the curing period or within 28 days of application.

- It is recommended to leave the formwork in place for at least 48 hours.

- The curing period should be at least 5 days.

- Curing should take place as soon as possible, at the latest when the surface of the material begins to set.

- Suitable curing agents can be used as an alternative to conventional curing methods.

5. Cleaning and maintenance

- The mixing tools should be cleaned with clean water immediately after use. Hardened material must be removed mechanically.

6. Special remarks

- Under certain conditions, cement-based building materials can lead to incompatibilities in connection with non-ferrous metals (such as aluminium, copper, zinc).

- Low temperatures slow down flowability and delay setting behaviour and strength development. High temperatures can accelerate setting behaviour and strength development and reduce the processing time of the material.

- Depending on the geometry and grouting height, the use of reinforcing steel may be necessary.

- The lateral grouting protrusion should be kept as small as possible (approximately 20-50 mm).

Health & Safety

BETEC® 110, 140, 180 and 516 are cement-based products and can therefore cause irritation to skin and eyes, which should be protected during use. wear gloves and protective eye shields. Wearing a dust mask is strongly recommended. Rinse splashes on the eyes or skin immediately with plenty of water. Consult a doctor if irritation persists. Full information can be found in the safety data sheet. The safety data sheet can be obtained from GCP website. GISCODE ZP1.

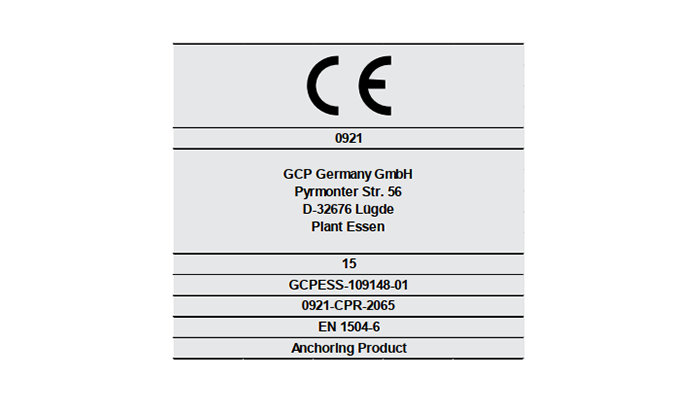

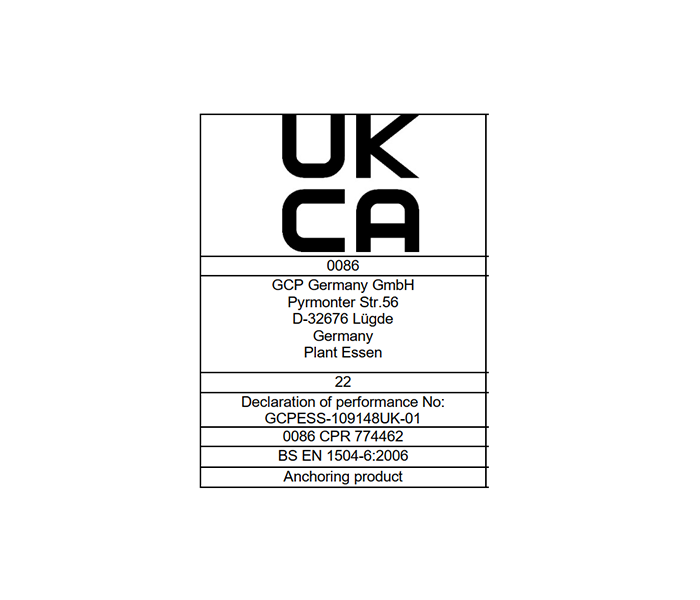

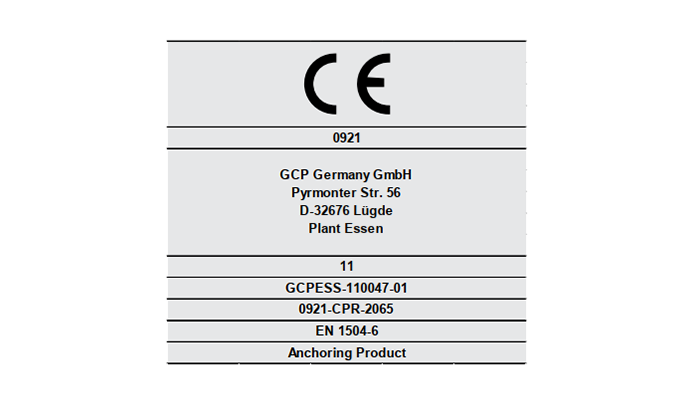

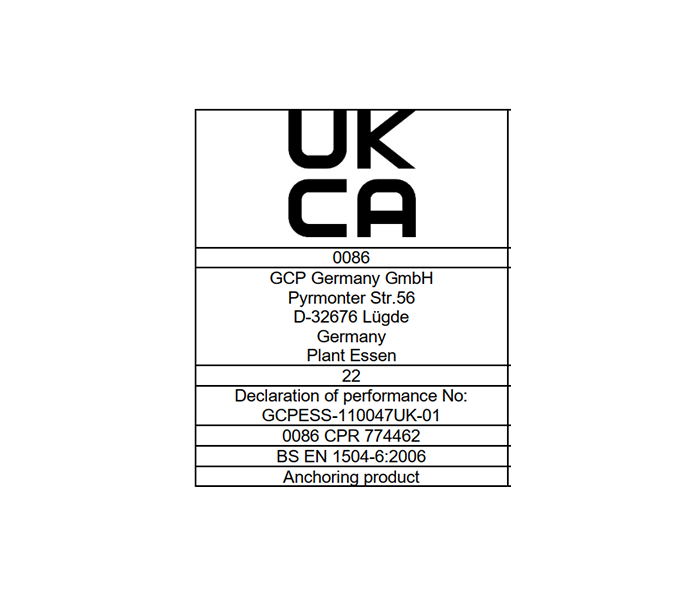

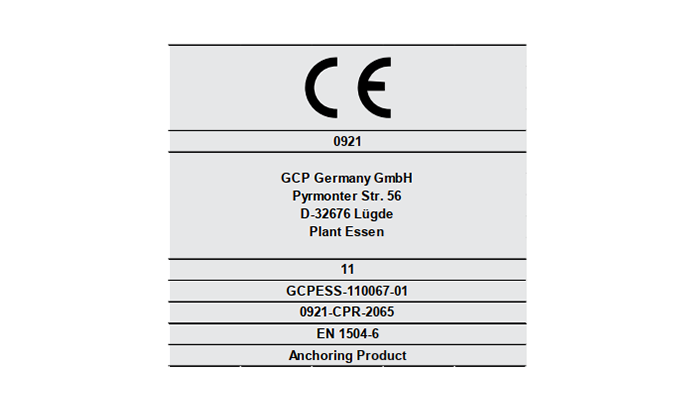

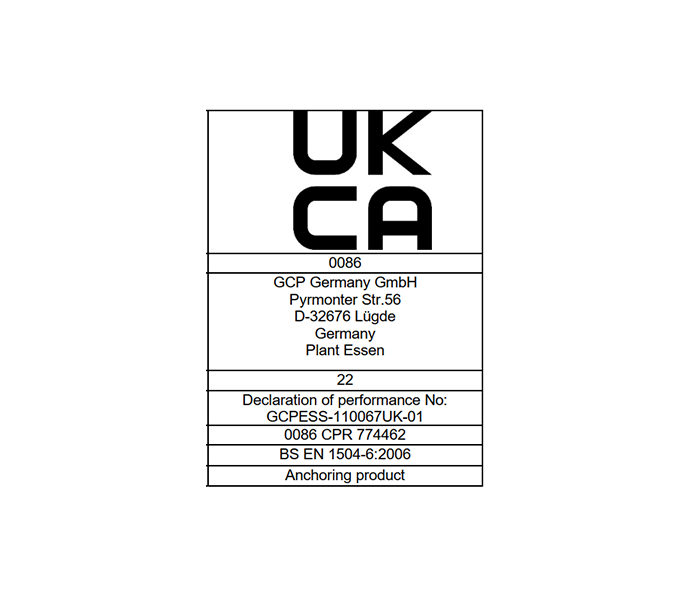

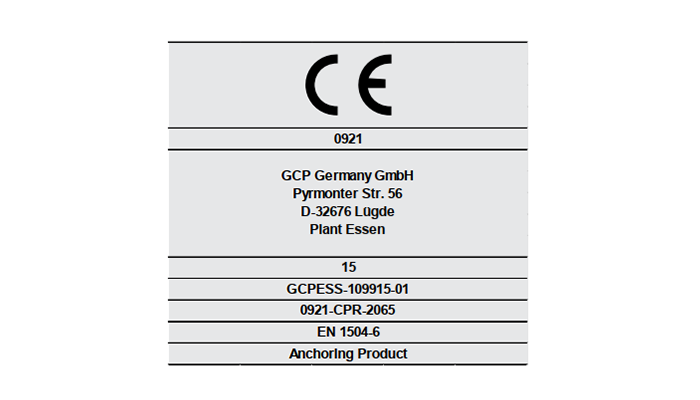

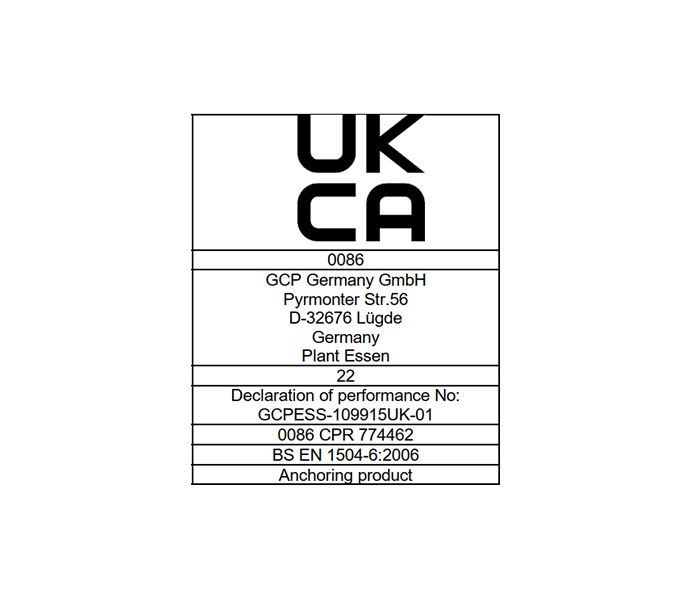

CE certificate

BETEC® 110

BETEC® 180

BETEC® 140

BETEC® 516

gcpat.uk | United Kingdom customer service: +44 (0) 1480 478421

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right

BETEC® is a trademark, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2025 GCP Applied Technologies Inc. All rights reserved.

Printed in Germany | 12/2025 | Data Sheet Nr. 1.11 RV 4

© Copyright 2026 Saint-Gobain Construction Chemicals UK Limited. All rights reserved. This document is only current as of the last updated date stated below and is valid only for use in the United Kingdom. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.uk. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-12-09

https://gcpat.uk/en-gb/solutions/products/betec-grouts-and-cementitious-mortars/betec-110-140-180-516