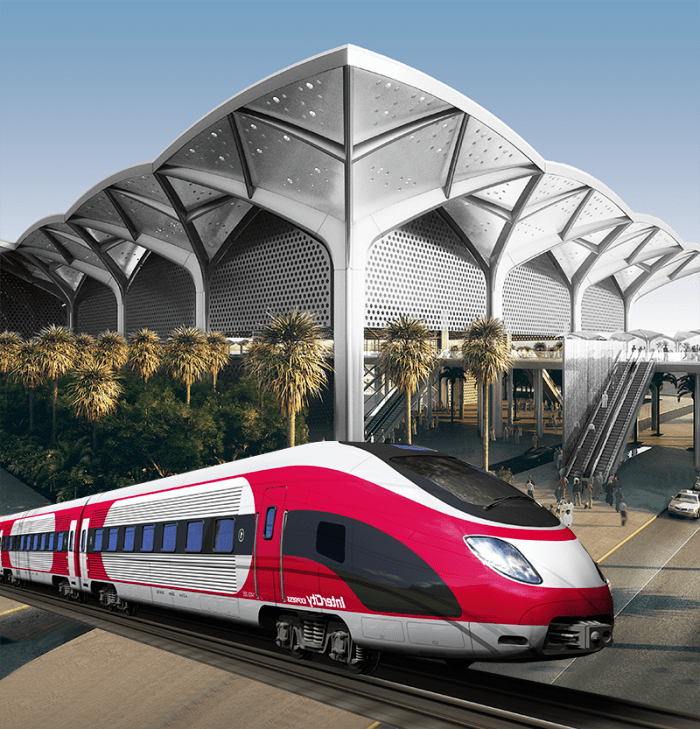

PREPRUFE® Protects High-Speed Middle East Railway

The Haramain High Speed Railway is one of the largest infrastructure projects in the Middle East. It's also one of the most challenging.

Extreme heat and desert conditions, aggressive ground conditions, high water tables and stringent time constraints—building four new stations in just four years—required the building crew to select high-performing construction products to ensure this railway stayed on track.

GCP Applied Technologies, therefore, offered engineers the high-performance PREPRUFE®waterproofing membrane to protect against the destructive effects of groundwater.

"The GCP PREPRUFE® 300R and BITUTHENE® 8000 HC membranes had considerable benefits as the waterproofing solution for the station in Jeddah", Rawabi Specialised Contracting Project Manager Hussein Ali Khodr said. "The nature of the project and the city stipulated the usage of proven state-of-the-art technology. As an applicator, the simplicity and flexibility of installation led to noticeable savings on engineering man hours".

The 450km high speed railway will link Islam’s holiest cities, Mecca and Medina, to the Red Sea coastal city of Jeddah, which is a key entry point for millions of pilgrims. The area between the four stations also covers an expanse 30 times greater than London's Trafalgar Square.

To further minimise risk and ensure continuity, BITUTHENE® 8000 HC waterproofing membrane was also specified to be post-applied and provide complete protection for the substructure walls from the aggressive soils. In total, the stations will consume a staggering 300,000 m2 of PREPRUFE® 300R and 150,000 m2 of BITUTHENE® 8000 HC.

Preprufe outperforms the competition

GCP Applied Technologies’ patented ADVANCED BOND TECHNOLOGY™ enables Preprufe to adhere directly to wet or dry concrete and to form an intimate and impenetrable seal. Unlike mechanically attached bonding technologies which risk water migration between the mesh interface and concrete, Preprufe is designed with synthetic adhesive layers and is combined with a robust HDPE film, providing a permanent physical barrier that protects structures against water and moisture, and chloride and sulphate attack even if their concentration changes over time.

PREPRUFE® is a durable and flexible waterproofing membrane that withstands harsh site conditions for a longer period of time than competitive waterproofing membranes. It can be walked on during installation without risking damage and is considerably faster and easier to install and detail than mechanically attached membranes. Protective layers of concrete or boards are eliminated, reducing the depth of excavation and spoil, whilst the number of additional materials required with mechanically attached technologies is minimised.

PREPRUFE® waterproofing membrane protects against the destructive effects of groundwater on one of the largest infrastructure projects in the Middle East.

Tags

- Mass transit

- PREPRUFE®

- Transportation Infrastructure

- Water stop

- Waterproofing