GCP Engineers are the Leading Authorities on Concrete Technology

Cement is the most man-made material in the world — 3.2 billion tons (2.85 B Imperial tons /2.9 B Metric tonnes) were manufactured in 2013 alone.

Cement is the material, the binding or gluing agent that holds concrete together. Traditional methods, however, that use raw materials like limestone to create concrete have high outputs of CO2, which pollute the environment. Substitutes like slag or fly ash are used because their greenhouse gas emissions are mush less when heated to the high temperatures required for concrete formation.

Cement Alternatives:

The trade-off for these alternative materials, like slag or fly ash, is that they provide less binding strength in the formation, however. This is where GCP Applied Technologies comes into the "mix". Infusing its unique, specially designed and patented additives into the cement, GCP's admixtures activate hydration at a higher rate. This builds strength in the cement much faster. By dissolving sediments such as iron in the cement, the admixtures accelerate hydration to form a higher strength concrete that is much more green, with less CO2 emissions.

GCP has many years of experience in this field, dating all the way back to the 1930s, as THE FIRST company ever to put chemicals into cement.

Some of its most important innovations since then include:

For more information on our wide range of Cement Additives, click here.

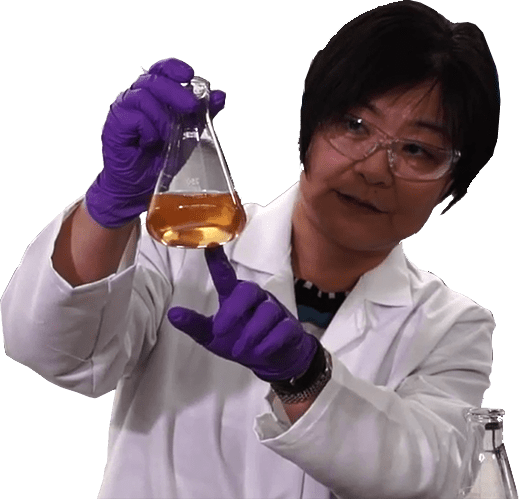

Seen above: Josephine Cheung is a foremost authority in cement admixtures, as GCP's Director of Research in Cement.

Tags

- Cement additives

- Cement production

- Precast producer

- Producer

- Quality improvers