SILCOR® 900HA

Fast-cure, hand-applied liquid waterproofing membrane for roofs, podium decks, terraces etc.

Product Description

SILCOR® 900HA is two component, hand-applied seamless liquid waterproofing that cures to form a high-strength, flexible, and fully-bonded waterproof membrane. Unlike conventional liquid membranes, SILCOR® 900HA is extremely durable with excellent wear and chemical resistance and does not normally require additional protection against mechanical damage.

Advantages

- Seamless – continuous waterproofing integrity with easy detailing.

- Fast application – single layer application.

- Fast cure – quick self-curing system for one day application and return to service.

- Fully bonded - eliminates water migration to prevent water tracking between membrane and substrate.

- Elastomeric - accommodates movements and bridges concrete shrinkage cracks.

- Durable – tough with excellent wear and damage resistance.

- Chemical Resistance – excellent fuel and chemical protection.

- Root Resistance – tested according to EN 13948.

- BBA Certificate

- European Technical Approval.

Principal Applications

New and remedial waterproofing of:

- Roofs

- Podium decks

- Terraces

- Walkways and foot bridges

- Balconies

- Green / Planted roofs

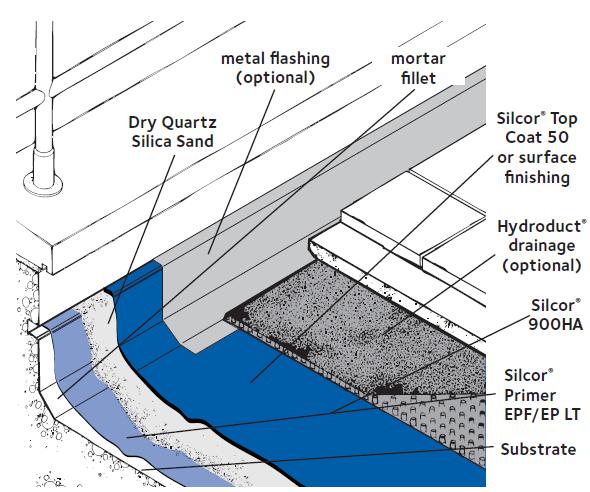

System Components

- SILCOR® 900HA – seamless waterproofing membrane.

- SILCOR® Primer EP LT – three-component epoxy primer fast curing at low temperatures for use 0°C - 20°C.

- SILCOR® Primer EPF – two-component epoxy primer for concrete substrates.

- SILCOR® Primer MT – two-component phosphate/epoxy primer for metal substrates.

- Dry Quartz Silica Sand – fine dry silica quartz sand for use with primers. Contact GCP for specification.

- HYDRODUCT® 200/ 650 (optional) – geocomposite drainage/ irrigation sheet.

- HYDRODUCT® Root Barrier (optional)

Design

SILCOR® 900HA hand-applied roof waterproofing system is satisfactory for use as a fully adhered waterproofing layer on new and existing flat (including those with zero-pitch) and sloping protected roof specifications e.g. inverted roofs, terraces, podium decks and covered walkways for pedestrian traffic.

Installation

1. Surface Preparation

Concrete

All surfaces should be dry, clean and free from loose particles, cement laitance, fungal growth, paint, grease and other contaminants that could affect adhesion. Where necessary, remove laitance mechanically by sand or grit blasting to provide an open pore substrate. Surfaces must be structurally sound and free of sharp protrusions, all defects in the substrate should be repaired with resin-based concrete repair mortars, used in accordance with the suppliers technical recommendations. Do not jet wash, as this will saturate the substrate and necessitate prolonged drying times. Max moisture content of concrete 5%. Concrete compressive strength should be minimum 15 MPa, 28 day cure. Minimum cohesive strength of concrete surface should be 0.8 MPa for limited access roofs and 1.5 MPa for public pedestrian access.All substrate cracks and joints should be raked to remove loose residues then primed with the appropriate SILCOR® primer. Fill all cracks with MS Fixer sealant.

Steel

Steel should be grit blasted to SA 2.5 specification or ground to remove the surface of the steel and any coatings. Solvent wipe the steel with acetone or a similar solvent prior to application of primer.

Bitumen Sheets

Only use SILCOR® Primer PU 30 on bitumen sheets (mineralised face). For concrete substrates, use SILCOR® Primer EPF.

All surfaces must be dry, clean, sound, free of dust, grease and any other contaminants that might affect adhesion.

Bitumen felts should be checked carefully. If the surface defects (cracks, blisters, poorly bonded laps, etc.) are less than 15% of the total surface area then it is feasible to apply SILCOR® Primer PU 30. All blisters in the bitumen sheets should be star cut and the substrate beneath dried fully with a vac and hot air gun. All cut edges and de-bonded laps should be re-bonded with ADCOR® Adhesive MS. Remove all un-bonded mineral stones.

Where bitumen sheet roofs have surface defects in excess of 15% of the total surface area, it is not feasible to apply SILCOR® Primer PU 30. Remove all bitumen sheets and residues from the substrate to expose the structural deck.

Use SILCOR® Primer EPF or SILCOR® Primer EP LT on all concrete substrates where bitumen sheets have been removed.

The substrate humidity before application of the primer must be less than 5%. The primer surface humidity before application of SILCOR® liquid membrane must be less than 5%.

2. Priming

Substrate temperature prior to application of both primer and membrane must be minimum 3°C above dew point. All primers should be applied only between +5ºC and +40ºC ambient, except SILCOR® Primer EP LT which should be applied only between 0ºC and +20ºC.

SILCOR® Primer EPF – 2 component epoxy primer for cementitious and masonry substrates should be applied at a typical consumption rate of 0.35 kg/m2 (see also separate product data sheet for SILCOR® Primer EPF). Coverage rates will vary depending on surface irregularity. The primer should be roller applied at a rate to give full substrate coverage but to prevent ponding. Leave the primer to dry and apply the first coat of SILCOR® 900 HA within 18 hours maximum. If application of SILCOR® 900 HA is delayed beyond this time, re-prime with a second coat of SILCOR® Primer EPF.

SILCOR® Primer EP LT – 3 component epoxy primer for cementitious and masonry substrates, fast curing at low temperatures (to be used between 0ºC and +20ºC). It should be applied at a typical consumption rate of 0.35 kg/m2 (see also separate product datasheet for SILCOR® Primer EP LT). Immediately following the application of the primer and while still wet, scatter dry, washed quartz silica sand diameter 0.4 mm - 0.8 mm onto the primer and cover fully. Leave the primer to dry completely then remove all loose sand by thorough brushing/scrubbing.

SILCOR® Primer MT – 2 component phosphate/epoxy primer for metal substrates should be applied within 24 hours (at 60% RH) of completion of surface preparation to prevent ‘flash rust’. Typical consumption rate is 0.15 kg/m2. Apply SILCOR® 900HA between 12 and 24 hours after application of SILCOR® Primer MT (20°C). If application of SILCOR® 900HA to SILCOR® Primer MT is delayed beyond this time, re-prime with a second coat of SILCOR® Primer MT.

SILCOR® Primer PU 30 - 1c PU primer for bitumen sheets (with mineralized face) should be applied by brush or roller, at a typical consumption rate of 0.20 – 0.30 kg/m2 Coverage rates will vary depending on surface irregularity. The primer should be roller applied at a rate to give full substrate coverage but to prevent ponding. Leave the primer to dry and apply the first coat of SILCOR® 900HA within 18 hours maximum. If application of SILCOR® 900HA to primer is delayed beyond this time, re-prime with a second coat of SILCOR® Primer PU 30.

3. Application

Application ambient temperature range 5°C – 40°C. Maximum humidity 85%. Substrate temperature should exceed the dew point temperature by a minimum of 3°C. During summer do not apply during the hottest part of the day.

SILCOR® 900HA hand applied liquid membrane is supplied in 10 kg units as a two component product. Part A and Part B are supplied in metal containers. Mixing should be with a minimum - 1000 W, variable speed drill and a helical blade mixing paddle, 80-100 mm dia. In winter climates, keep both Parts A & B as warm as possible to help mixing and application to substrate.

Open the Part B container and mix for two minutes until a homogeneous, lump free mix and a uniform colour is obtained. Shake the Part A container well before opening. Add the entire contents of the Part A container to the premixed B component and mix for at least one minute, until a uniform colour is obtained. The mixed product should have a uniform colour, free from streaks. Scrape any material from the side and bottom of the container to ensure thorough mixing.

Once A and B components are mixed, pour the mixture out of the pail onto the substrate immediately and spread with a 6 mm saw tooth polyurethane squeegee, 6 mm saw tooth steel trowel or similar. Straight edged squeegees and steel trowels can also be used, if preferred. Do not over-work the liquid as it is self leveling, surface imperfections such as pinholes and bubbles can be removed with a nylon spiked roller, but only within the working time of the liquid membrane.

Minimum recommended application thickness is 2.0 mm. Check thickness with a wet film thickness gauge, in a minimum of two locations every 10 kg of mixed membrane. The theoretical coverage rate (not including waste) at a 2 mm thickness is approx 2.4 kg/m2. Coverage rates will be reduced over rough and uneven substrates.

CAUTION:

Always apply the entire contents of the container as soon as possible after mixing. The reaction that occurs between Part A and Part B is exothermic (gives off heat) and accelerates the curing of the membrane. Do not replace pail lid after mixing.

SILCOR® 900HA is recommended for horizontal applications and can also be used on vertical surfaces up to 1.0 m high. Plan the application sequence so that there is no need to walk on the freshly applied liquid membrane.

SILCOR® 900HA cures typically within 30 – 60 minutes of application at 20°C and can hence take foot traffic as soon as it is tack free.

4. Laps

To achieve the best lap adhesion, fresh SILCOR® 900HA should be lapped onto dry, clean, previously applied SILCOR® 900HA membrane within 24 hours. Where previously applied SILCOR® is more than 24 hours old, lightly abrade all laps with a coarse sanding disc, glass paper or similar and remove all dust by thorough sweeping or vacuum cleaning. Solvent wipe with MEK or acetone. The minimum lap width is 100 mm.

6. Detailing

SILCOR® 900HA is formulated to be self-leveling and is not thixotropic. Hence for detailing of pipe entries and other penetrations through the liquid waterproofing, use BITUTHENE® LM (see separate product data sheet).

7. Cleaning Tools

Clean tools with MEK or acetone. Observe all health and safety advice for these products

8. Anti Slip Finishes

Where an anti-slip finish is required apply a third coat of SILCOR® 500 EM at a minimum rate of 0.9 kg/m², and broadcast at a 50% coverage rate with silica quartz aggregate, 0.8 - 1.2 mm dia, applied whilst the membrane is still wet. Remove all unbonded quartz aggregate and, if required for colour stability, apply SILCOR® Top Coat 50 in one or two coats.

NBS Specification Clause

Refer to Clause J31/130.

Chemical Resistance

SILCOR® 900HA is resistant to a wide range of chemicals. Contact GCP for specific details and recommendations.

Root Resistance

SILCOR® 900HA is resistant to root penetration and can be used for green roofs/decks without any additional root barrier

Health and Safety

For SILCOR® 900HA, SILCOR® Primer EPF, SILCOR® Primer EP LT and SILCOR® Primer MT read the product label and Safety Data Sheet (SDS) before use. Users must comply with all risk and safety phrases. SDS’s can be obtained from gcpat.com.

Warranties

GCP and trained contractors will provide warranties for individual projects. Contact GCP for further details.

Supply

| UNIT OF SALE | |

|---|---|

| SILCOR® 900HA (Resin) | 1.01 kg |

| SILCOR® 900HA (Iso) | 8.99 kg |

| SILCOR® Primer EPF (Part A) | 3.20 kg |

| SILCOR® Primer EPF (Part B) | 1.80 kg |

| SILCOR® Primer EP LT (Part A) | 3.16 kg |

| SILCOR® Primer EP LT (Part B) | 0.72 kg |

| SILCOR® Primer EP LT (Part C) | 1.12 kg |

| SILCOR® Primer MT (Part A) | 6.2 kg |

| SILCOR® Primer MT (Part B) | 0.9 kg |

| Storage | Store between 5°C & 25°C. |

| Shelf life | 12 months |

| Ancillary Products | |

| SILCOR® Top Coat 50 | Optional UV protective coating |

| HYDRODUCT® 200 / 650 | Optional drainage geocomposite sheets |

Liquid properties

| TYPICAL VALUE | TEST METHOD | |

|---|---|---|

| Solids Content | 100 % | ASTM D1644 |

| Specific gravity (Resin, Iso)1 | 1.2 g/cm3, 1.2 g/cm3 | |

| Coverage Rate (2 mm thickness) | 2.4 kg/m² | Internal |

| Pot Life | up to 8 minutes1 | Internal |

| Working Time | up to 15 minutes1 | Internal |

| Tack-Free Time | 30 minutes1 | Internal |

Footnotes:

1. At 23ºC.

All declared values shown in this data sheet are based on test results determined under laboratory conditions and with the product sample taken directly from stock in its original packing without any alteration or modification of its component parts.

Physical properties

| TYPICAL VALUE | TEST METHOD | |

|---|---|---|

| Resistance to hydrostatic head over 3.2 mm post formed crack | > 70 m | ASTM D5385 |

| Tensile Strength | 10 MPa | ASTM D412 |

| Elongation | 450 % | ASTM D412 |

| Tear Strength | > 40 kN/m | ASTM D624 |

| Adhesion to concrete | Concrete failure1 | ASTM D4541 |

| Adhesion to steel | > 4.0 MPa | ASTM D4541 |

| Shore Hardness | 75 A | ASTM D2240 |

Footnotes:

1. Tested on prepared, primed, and sand cast concrete

European Technical Approval

ETAG005 Levels of performance

| CHARACTERISTIC | LEVEL OF PERFORMANCE |

|---|---|

| Minimum thickness | 2.0 mm |

| Water vapour resistance factor (μ) | 2151 |

| Resistance to wind loads | >50 kPa |

| External fire performance | NPD1 |

| Reaction to fire | Euroclass E |

| Categorisation by working life | W2 |

| Categorisation by climatic zones | S |

| Categorisation by imposed loads | P3 at TH4 P4 at TH3 |

| Categorisation by roof slope | S1 |

| Categorisation by surface temperature - lowest - highest |

TL3 TH4 |

| Slipperiness [Slope (°)/friction coefficient] | NPD |

Footnotes:

1. External fire performance is dependent on the protection layer used in the roof specification. Deemed-to-satisfy inorganic coverings are listed in the Annex of Commission Decision 2000/553/EC.

gcpat.uk | United Kingdom customer service: +44 (0) 1480 478421

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

SILCOR is a trademark, which may be registered in the United States and/or other countries, of GCP Applied Technologies, Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2018 GCP Applied Technologies, Inc. All rights reserved.

This document is only current as of the last updated date stated below and is valid only for use in the United Kingdom. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.uk. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2022-11-24

https://gcpat.uk/en-gb/solutions/products/silcor-liquid-waterproofing/silcor-900ha